Features of Coil Container:

- 20’x8’x8’6” With hard open top & swing door header to load coils from the top.

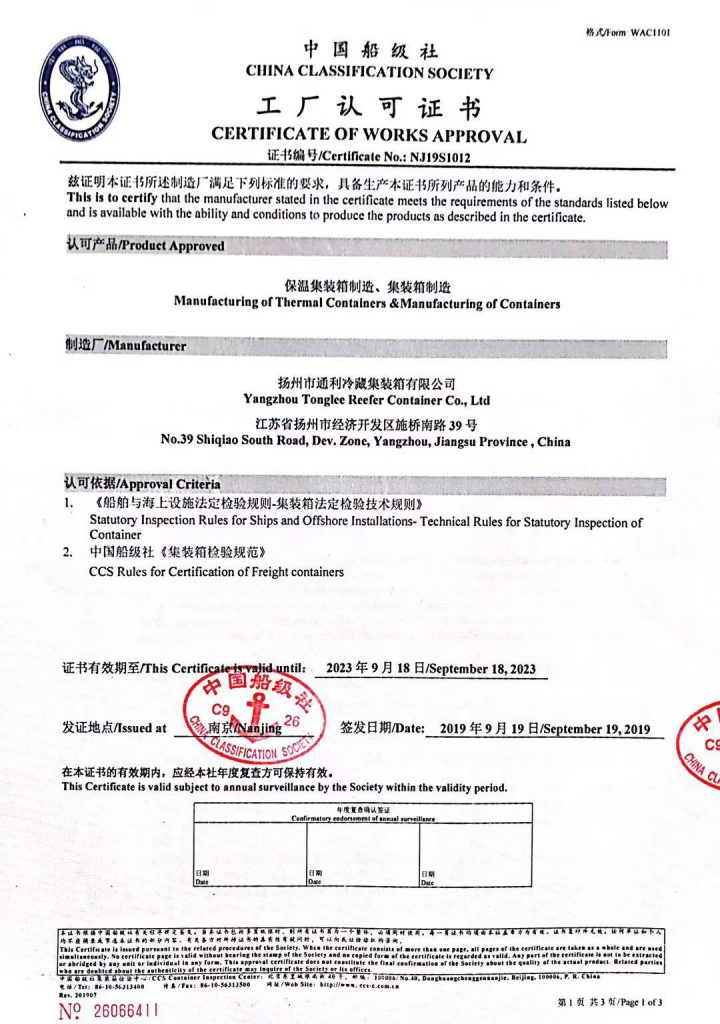

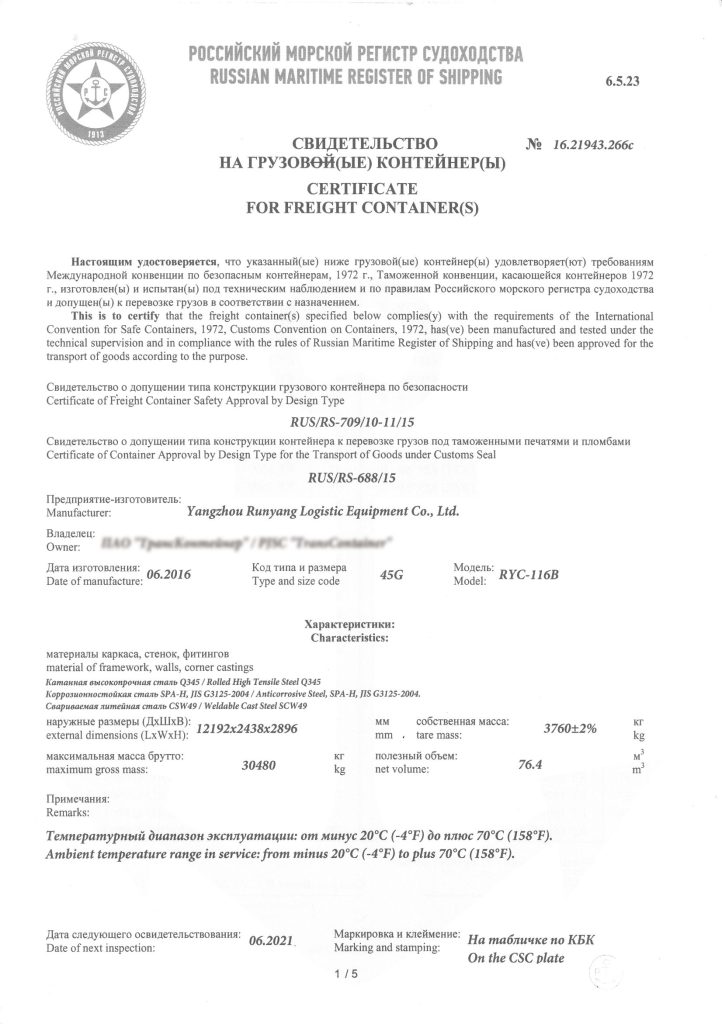

- With a CSC Certificate. Payload 31500kg. MGW.36000kg.Internal capacity 32.7 cu.m.Load coil diameter 600~1850 мм.

- With strengthened cross bars that have passed the collision tests on the Russian railway.

- Multifunctional: Cradles can be easily opened to load coils & put down to load steel sheets or other general cargos on the return way.

| SPEC. | Item | Value | Tolerance / Unit |

|---|---|---|---|

| Ext. size | Length | 6,058 | +0 мм |

| -6 мм | |||

| Width | 2,438 | +0 мм | |

| -5 мм | |||

| Height | 2,591 | +0 мм | |

| -5 мм | |||

| Int. size | Length | 5,898 | мм |

| Width | 2,350 | мм | |

| Height | 2,362 | мм | |

| Door opening size | Length | 2,338 | +0 мм |

| -5 мм | |||

| Height | 2,262 | +0 мм | |

| -5 мм | |||

| Roof open size | Length | 5,570 мм | |

| Width | 2,212 мм | ||

| Internal Capacity | 32.7 CU.M | ||

| MGW | 36,000 KG | ||

| Tare weight | 4,500 KG | ||

| Max. Payload | 31,500 KG | ||

| Stacking test load (Per post) | 97,200 KG | ||

| Cradle floor’s length | Total 4 sets (8 pieces) cradles each container, total length 5648mm, if deduct the cross bars’ length, the cradle length is 4870mm. | ||

| Max.. payload (coil loading) | If loading 3-4 coils, the max total payload is 31.5 tons. If loading only one heavy coil in the middle, the max load is 28 tons. | ||

| Coil’s diameter range | 600~1850 мм | ||

| Cross bars’ height | A total of 8 pieces of cross bars in each container, in 2 layers. Upper: 820mm, Lower: 370mm from the floor. | ||

More Types of Coil Containers:

20’x8’x8’6” Coil container with fixed cradle.

- With a hard open top.

- With a removable swing door header.

- Payload 28 tons.

- With a CSC Certificate.

20’x8’x9’6” Coil container, with collapsible cradles.

- Multifunctional: Cradles can be easily opened to load coils& put down to load general cargos on return way.

- Payload 29.2 tons.

- With a CSC Certificate.

- With a hard open top, be customized with a fixed door header/swing door header.