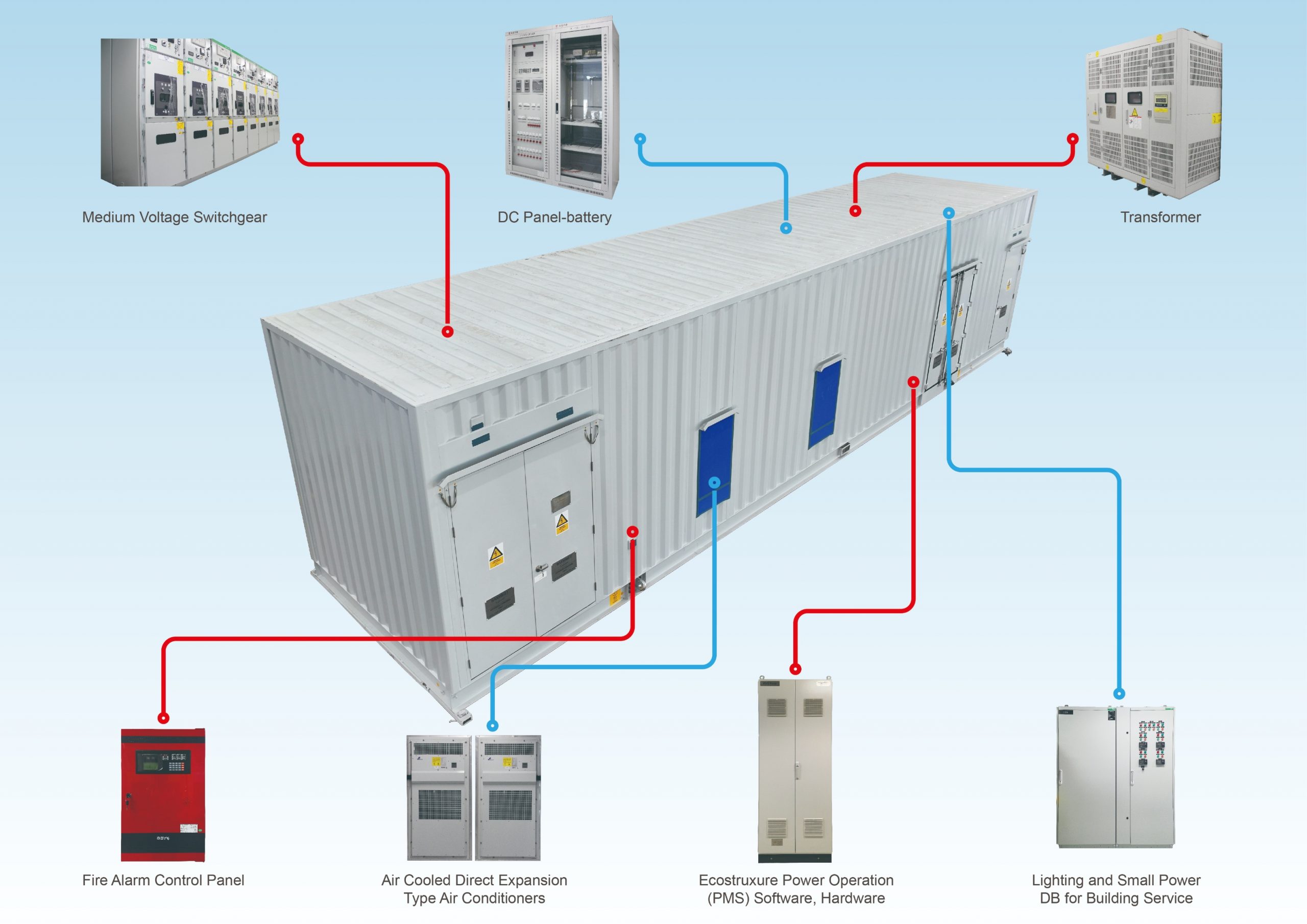

E-House (prefabricated electrical room) Container is a prefabricated walk-in modular steel structure outdoor box that can accommodate medium voltage (MV) and low voltage (LV) switchgear and auxiliary equipment. It is often called PowerHouse or Power Distribution Center. It is an efficient and mobile electrical solution designed to reduce on-site construction and deploy quickly.

Features and advantages of E-House Container

Reduce on-site construction: E-House Container greatly reduces on-site construction and installation time through prefabrication and modular design, and is particularly suitable for areas with a shortage of professionals and expensive labor.

- Efficient integration: E-House Container integrates professional equipment such as electrical, instrumentation, structure, HVAC, and fire protection, and ensures high integration and efficient operation through complete testing and manufacturing in the factory.

- Mobility: E-House can be installed on a pallet truck for easy transportation and transfer, and is suitable for scenarios that require frequent movement or use in different locations.

- Environmentally friendly: Adopt SF6 substitutes to reduce the impact on the environment and meet the requirements of sustainable development.

Application scenarios

E-house container is widely used in various scenarios that require efficient and rapid deployment, including but not limited to:

- Power generation, oil, natural gas, mineral mining and process industries: In these fields, E-House Container can significantly reduce on-site construction and installation time, and improve work efficiency.

- New energy fields: such as solar energy, wind power, energy storage, etc., E-House Container provides standardized solutions, reduces costs and improves project predictability and efficiency.

- Infrastructure construction, such as temporary/emergency electricity, electric vehicle charging facilities, etc., and the modular design of E-houses give them significant advantages in these fields.

The E-House Container is a prefabricated modular steel structure designed to house medium and low-voltage electrical equipment, offering features such as reduced on-site construction time, efficient integration, mobility, and environmental sustainability. It is widely used in industries like power generation, mining, oil and gas, renewable energy, and infrastructure, providing a cost-effective and flexible solution for rapid deployment and efficient operation in diverse scenarios.