A Bulk Container is a container with a loading port at the top and a releasing port at the bottom, mainly used to ship unpackaged solid, granular, and powdered goods. In addition to the door, a Bulk Container also has 2 to 3 loading ports at the top of the box. When using it, it is important to keep the box clean and smooth to ensure easy unloading of goods from the door.

Bulk Containers are widely used to store soybeans, rice, malt, flour, corn, all kinds of feed, cement, chemicals, and other bulk powder or granular goods. When loading grain, some Bulk Containers are equipped with fumigation attachments on the top.

Choosing a Bulk Container is not only about functionality but also about optimizing the bulk container cost. Bulk Containers help save on packaging expenses, reduce dust damage to human health and the environment, improve handling efficiency, and significantly lower overall logistics costs.

CIMC TLC|RYC Bulk Container Introduction

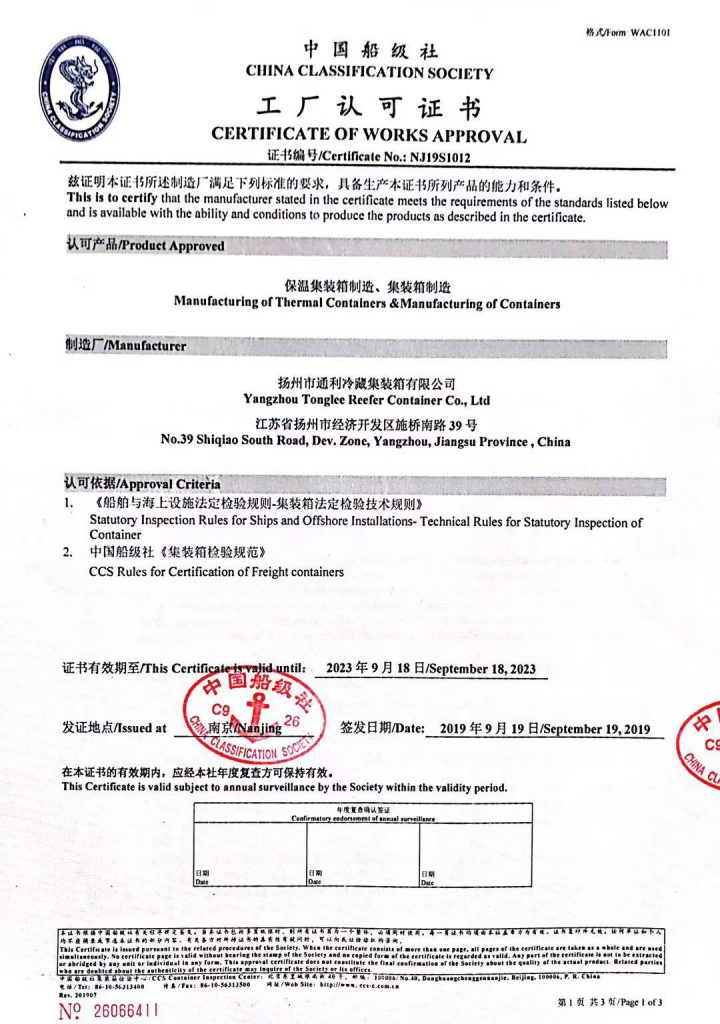

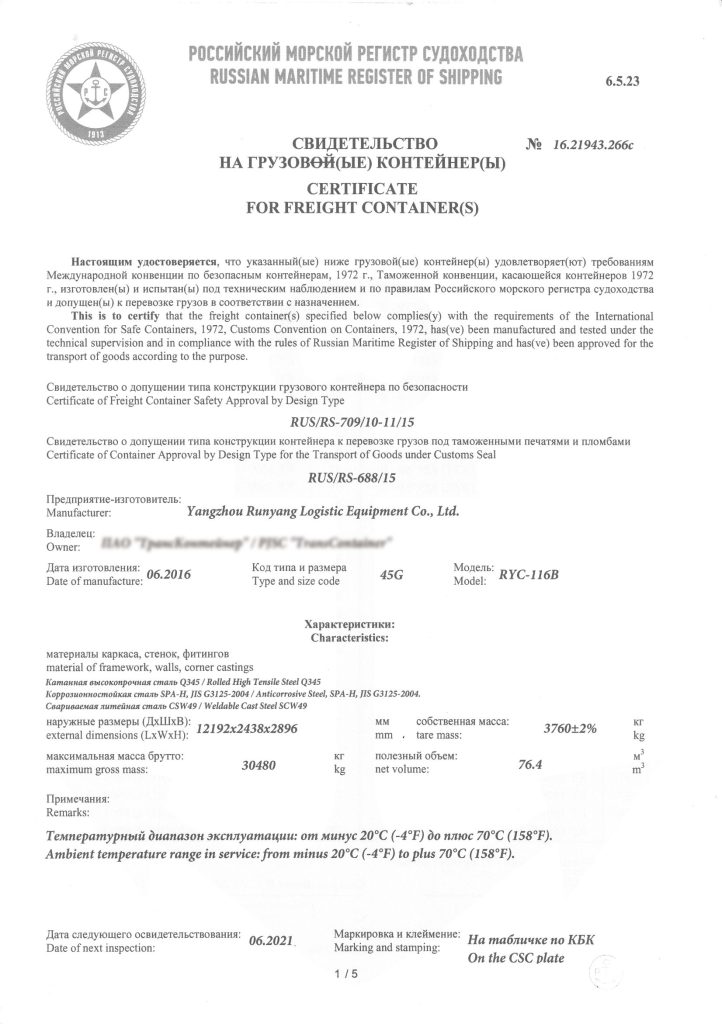

- Bulk Container usually uses an ISO 20ft reefer container or a 20’ high cubic container. CIMC TLC|RYC Bulk Container has passed the CSC certification.

- Bulk Container can be used with an inner bag for the storage and transportation of bulk granular cargo.

- Square pipes are used as inner pocket plugs.

- As an optional fixing device, the roof entrance can be changed to a 2 or 3 square hatch, or a steel rope sliding hatch that can be operated from the ground (patented design).

- As an optional choice, the rear door can be replaced with a self-discharge type tail gate(patented design).

- CIMC TLC|RYC Bulk Container is widely used in the field of chemical transportation and clean energy transportation.

- Roof hatches for loading from the top.

- Small discharge door in rear or front.

Bulk Container Structural Features

- On top of the box, there are several loading ports after loading can be completely closed.

- The inner wall of the Bulk Container is lined with a whole sheet of waterproof plywood. For easy removal of bulk cargo and easy cleaning after use, the plywood is coated with fiberglass.

- The canvas funnel is usually provided on the inside of the rear door frame of the Bulk Container. Depending on the box type, some Bulk Containers are directly equipped with a discharge port on the rear door. When unloading, the container is tilted up by an automatic dump truck, so the cargo can be safely discharged from the discharge port.

- When loading ordinary groceries with the Bulk Container, the canvas funnel can be removed and folded, and stored in a fixed position inside the top of the box.

Bulk Container Data Sheet

| External Size | 6058(L) x 2438(W) x 2591(H) mm | |

| Internal Size | 5898(L) x 2350(W) x 2366(H) mm | |

| Rear Door Opening | 2343(W) x 2280(H) | |

| Internal Cubic Capacity | 32.8 CU.M | |

| Maximum Gross Weight | 30480 KGS | |

| Tare Weight | 2190 KGS | |

| Maximum Payload | 28290 KGS | |

| Stacking Test Load ( Per Post) | 86400 KGS | |

| External Size | 6058(L) x 2438(W) x 2591(H) mm | |

| Internal Size | 5898(L) x 2352(W) x 2352(H) mm | |

| Tare Weight | 2600 kg | |

| Internal Cubic Capacity | 32.6 Cu.m | |

| Maximum Payload | 27880 kg | |

| Roof | T2.0 mm SPA-H, with 3 circular type hatches | |

| Side wall& End wall | T2.0 mm SPA-H corrugation panel | |

| Floor | T6.0 flat plate or checker plate | |

| Door | T2.0 mm SPA-H corrugation panel door opening width 2343mm, with 7 square tubes as inner bag stopper | |

| Optional fixtures | square hatches, slide hatches(operation in the ground) normal tailgate with different heights, special tailgate with linkage system special tailgate without Manual open(patent design), inlet and outlet design, plywood lining | |