CIMC TLC|RYC has more than 25 years of design and manufacturing experience for reefer containers. Thanks to the large-scale and professional PU foaming production line, the reefer containers with high thermal isolation performance.

Reefer Container Common Aliases

Reefer containers can also be called Reefer shipping containers, reefer sea containers, freezer sea containers, reefer sea containers, freezer shipping containers, reefer shipping containers, 20ft reefer, Special reefer containers, etc.

Operational Environment

The container is to be designed and manufactured for the carriage of reefer container (frozen, chilled) foodstuffs and general cargo by land (on road or rail) and by sea (above or below deck) throughout the world and will range from -30°C to +70°C without effect on the strength of the basic structure. A mechanical refrigeration unit of a “one-piece picture frame type” will be fitted to the front-end frame. The container is designed with a refrigeration unit to maintain the inside space temperature at -25C° to +25C°.

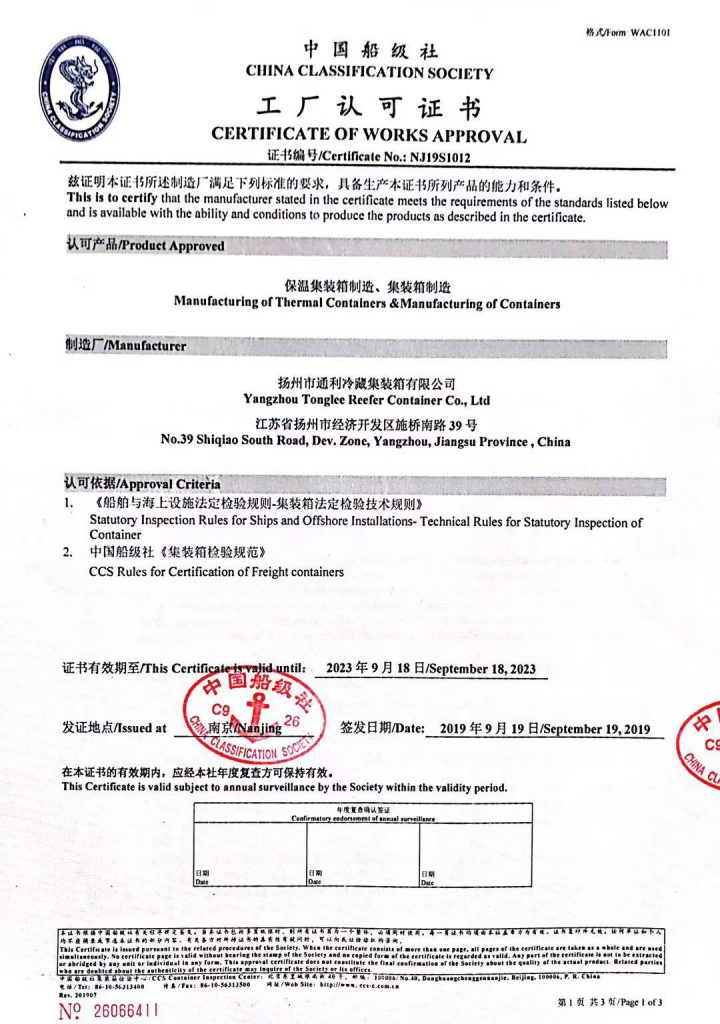

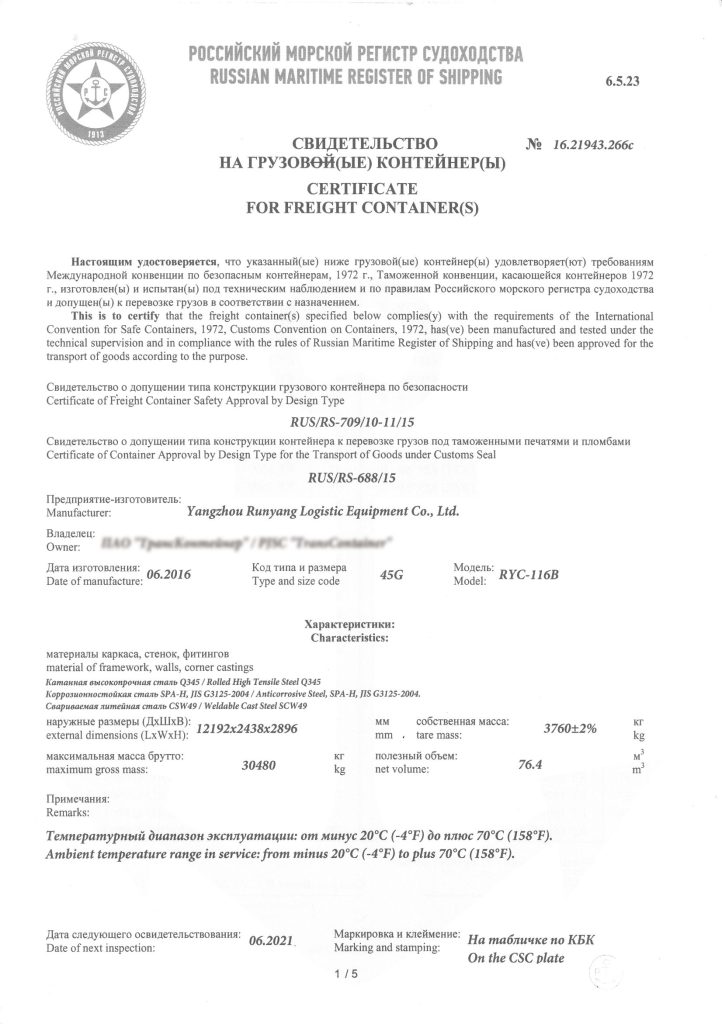

Regulations and Standards

- ISO/TC-104

668 Dimensions and ratings (1995 edition)

6346 Coding, identification and marking (the third edition, 1995)

1496/2 Specification and testing thermal containers (1996 edition)

1161 Specification of corner fittings (1984AMD.1:2007 edition)

- TIR Requirements and Certificate: approved by the Classification Society.

- Timber Component Treatment and Certificate. There will be no exposed timber in the construction.

- CSC Requirements and Certificate: In compliance with the “International Convention for Safe Containers”.

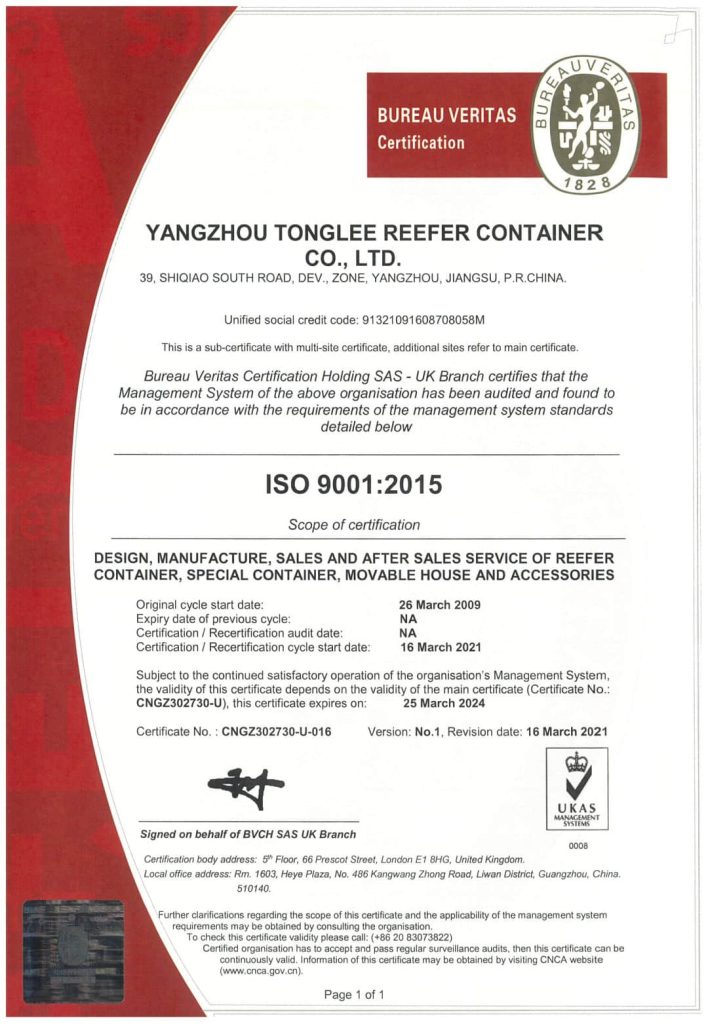

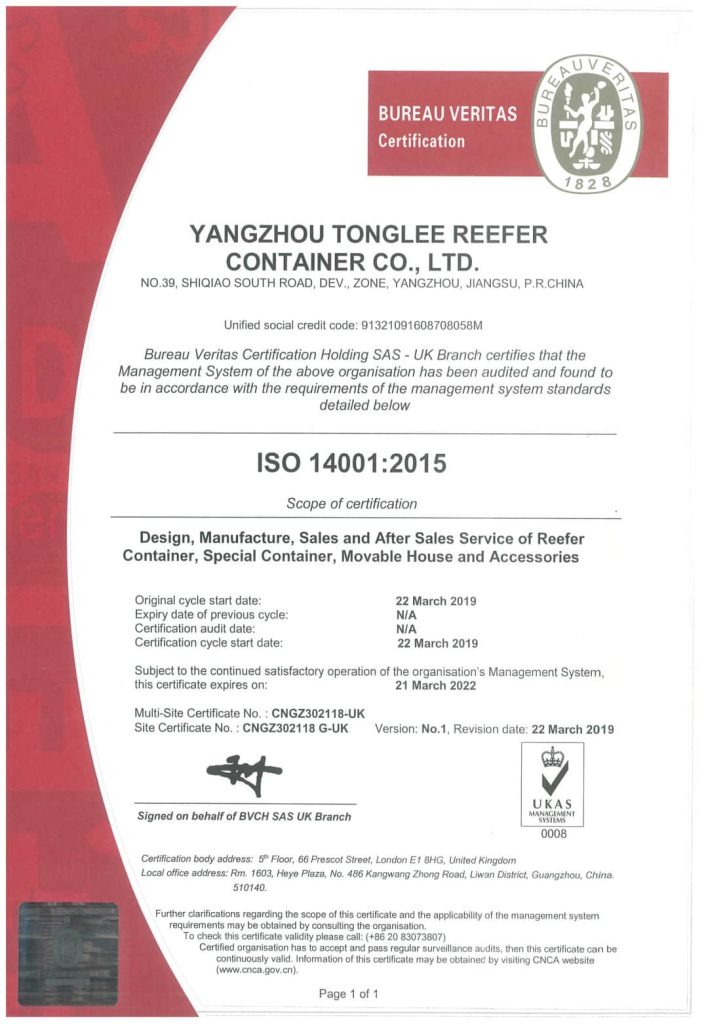

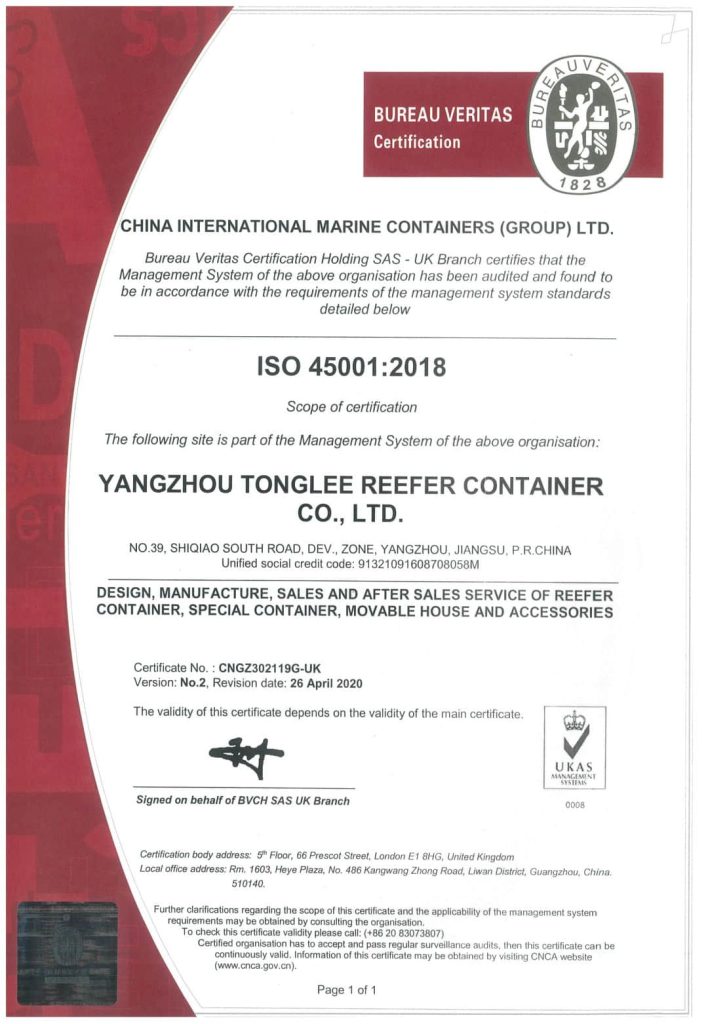

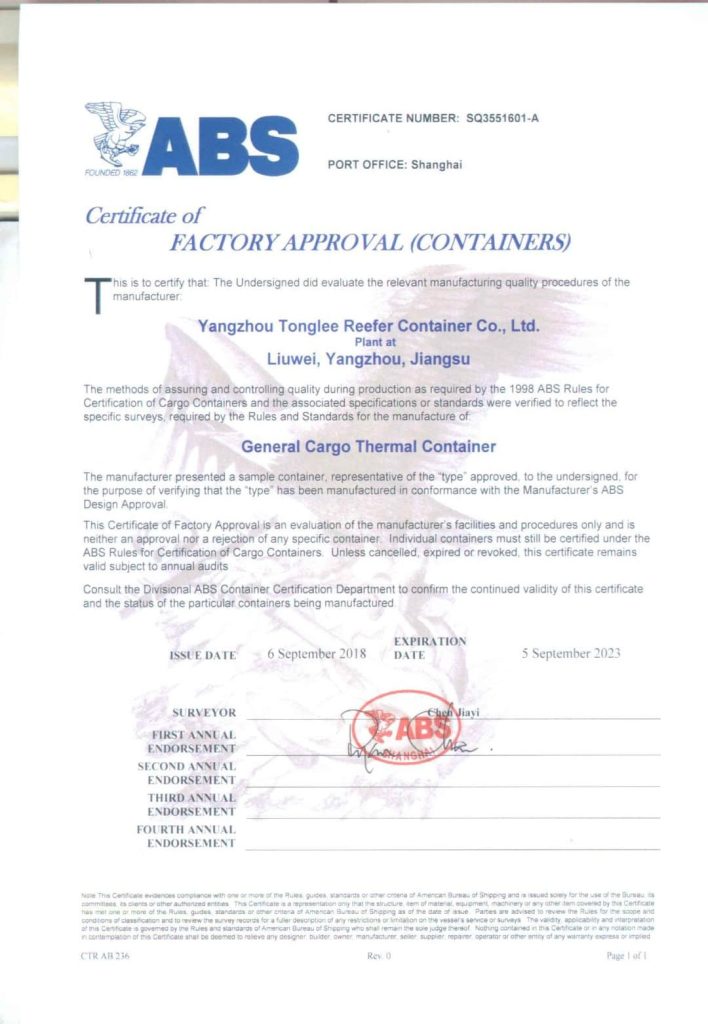

- Classification Society: All Containers will be certified by ABS / BV / LR.

Handling

The containers will be constructed to be capable of being handled without permanent deformation, which will render them unsuitable for use under the following conditions:

1.3.1 Lifting full or empty at top corner fittings employing spreaders fitted with hooks, shackles, or twistlocks.

1.3.2 Lifting full or empty at bottom corner fittings using slings with terminal fittings at sling angles of 45 degrees. To the horizontal plane.

Transportation

The container will be constructed to be suitable for transportation in normal operating conditions and the following modes:

- Marine——-In the cell guide: 9 high stacked (based on 24,000kg)

on the deck: 4 high stacked and secured by vertical and diagonal lashings

- Road——–On flatbed or skeleton chassis, secured by twist locks or equivalent ones at the bottom corner fittings.

- Rail———-On the flat cars of special container cars secured by twist lock or equivalent ones at the bottom corner fittings.

Reefer Container Applicable Scene

Vegetable, fruit, and meat transportation and storage maintain the goods at a certain low temperature.

Features of Reefer Container

The biggest feature of it is effective thermal insulation and high mechanical strength.

In terms of ensuring the thermal insulation of the reefer container, the material commonly used in the industry is polyurethane foam.

When the density of polyurethane foam is 40kg/m³, its thermal conductivity is the lowest. In the actual production process, to ensure that the polyurethane foam has a particular strength, reduces the void rate, and takes into account factors such as leakage during foaming, the design density is slightly greater than 40kg/m³.

The wall thickness of the reefer container is generally between 50-120mm, and the partial wall thickness of reefer container for special purposes can be reduced to 30mm.

Reefer Container Selection

It is essential for the transportation and storage of perishable goods/products (such as food and temperature-sensitive medicines).

For the successful delivery of frozen products, it is important to ensure the following:

- Uninterrupted cold chain transportation;

- Appropriate cooling technology;

- Choose the right insulation material, size, and container design.

Different products have different temperature requirements. Therefore, understanding the temperature requirements of each product in the transportation route is equally important for the successful selection of a reefer container. For example, blood needs to be stored between 2-6°C, drug vaccines must be kept at (-70)-5°C, and frozen food must be held at -18°C.

Requirements for using Reefer Container

- After the reefer container is loaded, the original quality of the reefer or frozen goods should be checked and stated on the manifest.

- In the process of packing, the principle of loading and stacking should be strictly complied with to avoid unbalanced cooling caused by short-circuiting cold air and reduce the refrigeration efficiency of the reefer container refrigeration device.

- When the frozen goods are transported over a long distance, the difference between the set temperature in the box and the set temperature cannot exceed 3°C. For the transportation of reefer goods, the temperature error should not be greater than 0.5°C, preferably not greater than 0.25°C.

- They transport fresh fruits, vegetables, etc., and the air vents should be opened in time for ventilation. However, when transporting frozen goods, the tuyere should be closed.

- Carton-packed cooling goods should be ventilated in time according to the outdoor temperature and humidity during transportation to keep the air in the box dry and prevent condensation on the outer surface of the box.

Classification of Reefer Container

According to the ISO/TC-104, 668 Dimensions and rating standard, reefer containers can be divided into 10’, 20’, 30’, 40’, and 45’ according to the length of the container. 30’ containers are generally not used, and the most used containers are 20 ’ and 40’in in length.

CIMC TLC|RYC Reefer Container Features

- 20’/40’H reefer container, complying with ISO size, CSC, and Customs regulations, suitable for intermodal transportation.

- Its outer panel material is made of muffler-grade stainless steel for high-grade protection to get containers’ long life, light tare weight, which can be loaded with more cargo, and high insulation properties.

- Reefer container K value less than 0.4W/m2.K, which can save energy, is widely used for the transportation of fresh fruit, flowers, meats, vegetables, medicine, and electrical equipment.

Advantages of Reefer Container

- First, they provide a cost-effective solution for transporting perishable goods. Containers can carry a large amount of goods, reducing unit transportation costs.

- Second, reefers have a lower carbon footprint than air or road freight. The use of sea freight reduces greenhouse gas emissions and contributes to more sustainable supply chains.

- Third, it provides a high degree of security for the goods. The containers are sealed and can only be opened at the port of destination, which reduces the risk of theft or tampering.

Application of Reefer Container

- In the food and beverage industry, coolers are used to transport fresh produce, frozen meat, seafood and dairy products. They are also used to transport wine and beer that require a specific temperature range to preserve their taste and quality.

- In the pharmaceutical industry, it is used to transport vaccines, medicines, and other medical products that require strict temperature control.

- Chemical manufacturers also use it to transport hazardous chemicals that need to be kept within a specific temperature range.

Maintenance and Safety of Reefer Container

To ensure the safe and efficient operation of the reefer container, regular maintenance is required. Refrigeration systems and insulation should be checked and serviced regularly to prevent any failures during transport. It is also important to follow the manufacturer’s container handling guidelines to avoid damage to the cargo or the container itself.

In terms of safety, reefer containers are designed to meet international sea container standards. They go through a rigorous testing and certification process to ensure they can withstand the stress of ocean shipping. However, proper handling procedures must be followed when loading and unloading containers to avoid accidents or injuries.

40′ H Reefer Container

| Exterior size | L12192XW2438XH2896 mm | ||||||||

| Tare weight | 4600 kg (Machine included) | Interior size | L11580xW2288XH2540 mm | ||||||

40′ H Reefer Container Data Sheet

| Base Structure | Gooseneck tunnel plate | ISO standard design | Insulation | PU | Density | 60 | KG/m3 | ||

| Thickness | 77/130 | mm | |||||||

| Floor | Floor: 63.5mm aluminum extrusion | Other: 4 sets of drainage at four corners | |||||||

| Sub-floor: 1.6mm Corten steel | |||||||||

| Roof | Outer roof pannel | Several pieces of 0.8mm MGSS panel jointed together | Insulation | PU | Density | 40 | KG/m3 | ||

| Ceiling | Several pieces of 1.27mm aluminum sheet jointed together by exclusive technology | Thickness | 80 | mm | |||||

| Others: several roof bows | |||||||||

| Side panel | Outer panel | Several pieces of 0.8mm MGSS panel jointed together by TIG welding | Insulation | PU | Density | 40 | KG/m3 | ||

| Sidelining | Several pieces of 0.7mm HGSS sheet jointed together by | Thickness | 60 | mm | |||||

| Others: The Rolled top and bottom side rail is made of 4.0mm Corten steel | |||||||||

| Side posts fixed to outer panels by resistance-welding welded to the top/bottom side rail | |||||||||

| Front & Rear frame | Welded Corten steel frame to be suitable for machine and door installation | ||||||||

| Door | Outer panel: 1.2mm MGSS, Door lining: 0.7mm HGSS. PU Insulation: 55kg/m3 density and 75mm thickness | ||||||||

| 5 pieces of Aluminum extrusion hinges and two sets of locking gear systems at each door | |||||||||

Preservation—RAL9010 Color Code For the Outer Surface

| Corten steel | Exposed of Corten steel: 30um rich zinc primer + 40um epoxy primer + 50um PU | ||||||||

| Hidden Corten steel: 10 μm rich zinc primer | |||||||||

| Underneath: 30um rich zinc primer + 200 um bitumen | |||||||||

| MGSS | Outer: 40um epoxy primer + 50um PU | ||||||||

| Stainless Steel | Hidden area: foamboard | ||||||||

| Air Leakage | Max. 5m3/h at 250Pa | ||||||||

| U value | Max.36.5kcal/k/h at 20°C temperature difference between outer and inner | ||||||||

20‘ Reefer Container

| Exterior size | L6058XW2438XH2591 mm | ||||||||

| Tare weight | 3000 kg (Machine included) | Interior size | L5450xW2288XH2292 mm | ||||||

20‘ Reefer Container Data Sheet

| Base Structure | Forklift pocket | 6.0X116X360 | mm | Insulation | PU | Density | 60 | KG/m3 | |

| Center distance of FLP | 2050+/-30 | mm | Thickness | 77/130 | mm | ||||

| Floor | Floor: 40mm aluminum extrusion | Other: 4 sets of drainage at the four corners | |||||||

| Sub-floor: 1.6mm Corten steel | |||||||||

| Roof | Outer roof pannel | several pieces of 0.8mm MGSS panel jointed together by | Insulation | PU | Density | 40 | KG/m3 | ||

| Ceiling | Several pieces of 1.27mm aluminum sheet exclusive technology | Thickness | 80 | mm | |||||

| Others: several roof bows | |||||||||

| Side panel | Outer panel | Several pieces of 0.8mm MGSS panel jointed together | Insulation | PU | Density | 40 | KG/m3 | ||

| Sidelining | Several pieces of 0.7mm HGSS sheet jointed together | Thickness | 60 | mm | |||||

| Others: The rolled top and bottom side rail is made of 4.0mm Corten steel | |||||||||

| Side posts fixed to outer panels by resistance-welding welded to the top/bottom side rail | |||||||||

| Front & Rear frame | Welded Corten steel frame to be suitable for machine and the door are installed | ||||||||

| Door | Outer panel: 1.2mm MGSS, Door lining: 0.7mm HGSS. PU Insulation: 55kg/m3 density and | ||||||||

| 4 pieces of Aluminum extrusion hinges and two sets of locking gear systems at each door | |||||||||

Preservation—RAL9010 Color Code For the Outer Surface

| Corten steel | Exposed of Corten steel: 30um rich zinc primer + 40um epoxy primer + 50um PU | ||||||||

| Hidden Corten steel: 10 μm rich zinc primer | |||||||||

| Underneath: 30um rich zinc primer + 200 um bitumen | |||||||||

| MGSS | Outer: 40um epoxy primer + 50um PU | ||||||||

| Stainless Steel | Hidden area: foamboard | ||||||||

| Air Leakage | Max. 5m3/h at 250Pa | ||||||||

| U value | Max.21kcal/k/h at 20°C temperature difference between outer and inner | ||||||||

CIMC TLC|RYC Reefer Container Service Details

| Pre-sales service | Technical and commercial consultant Customized design and engineering |

| Return Policy/After-sales Service | 1-year warranty for the structure 3 years for painting 5 years for decal |

| Lead time | 60 days after order confirmation |

| Transportation Method | Ocean, Railway, Road |

| Freight and transportation period | Confirmed according to the specific destination |

| MOQ | 1 unit |