Offshore Living Quarter can often be called modular living quarter, offshore accommodation building, Offshore Pressurized Mud Logging Cabin, offshore bedroom or offshore accommodation.

For marine construction and exploration, there are many projects that require many days of work at sea to complete. In order to ensure the construction progress of the project, the construction personnel usually have to live at sea for a long time, Offshore Living Quarter is the most economical and convenient living equipment.

CIMC TLC|RYC Offshore Living Quarter can be equipped with freshwater recycling units to reduce unnecessary freshwater waste, while rainwater at sea can also be treated into usable freshwater resources. At the same time, solar power generation can be used to solve the electricity problem of some Offshore Living quarters, saving energy and environmental protection.

CIMC TLC|RYC Offshore Living Quarter can also be equipped with dormitories, meeting rooms, electrical distribution rooms, changing rooms, and other facilities to meet people’s daily work and living needs at sea.

CIMC TLC|RYC Offshore Living Quarter Introduction

- Accommodate up to 2, 4, 8 individuals

- Comply with the requirements of ILO on personnel accommodation, reasonable layout, and high utilization rate

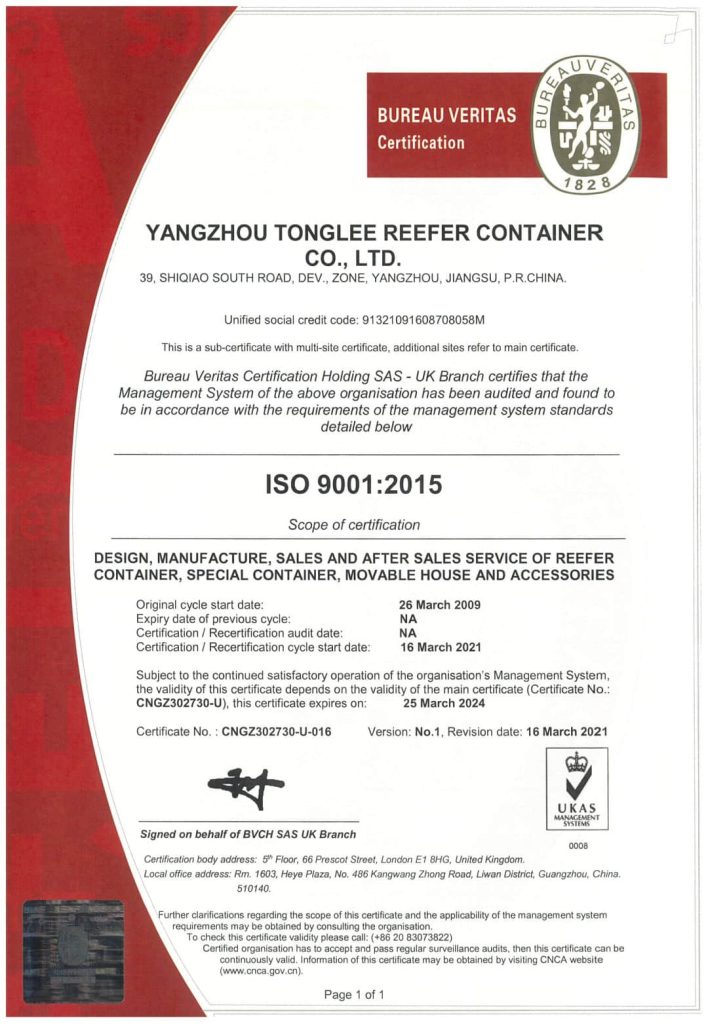

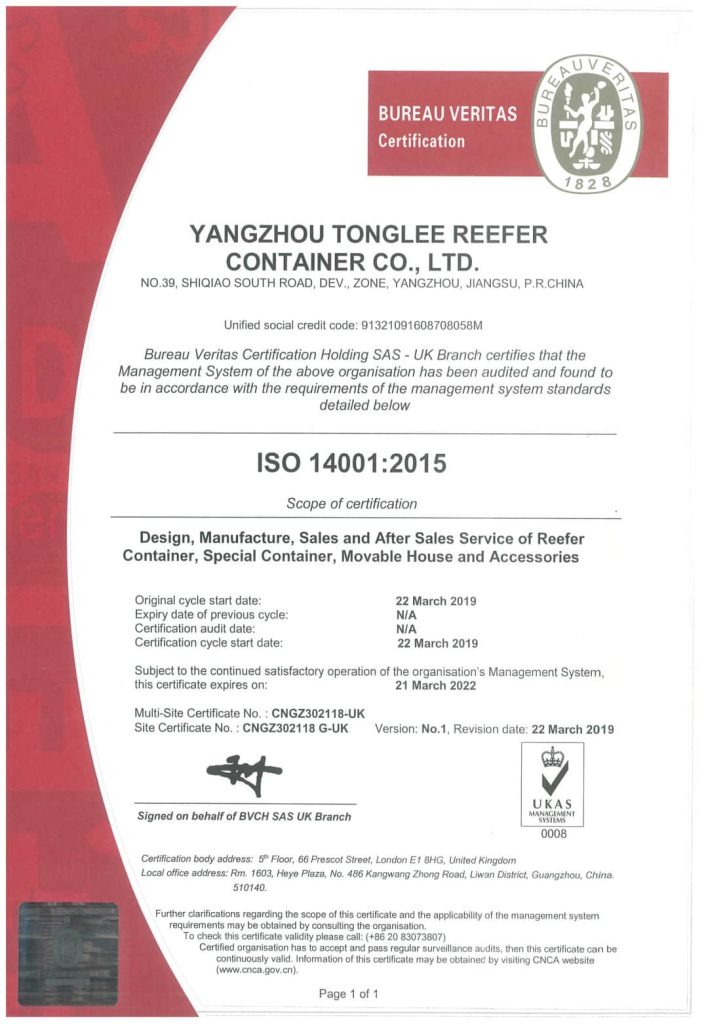

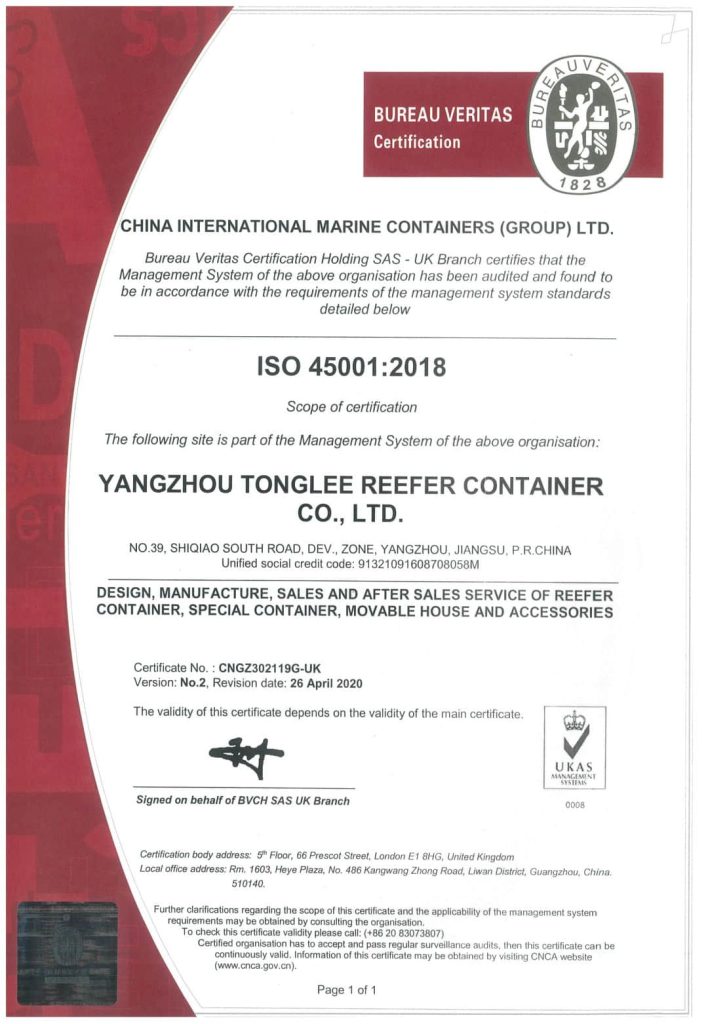

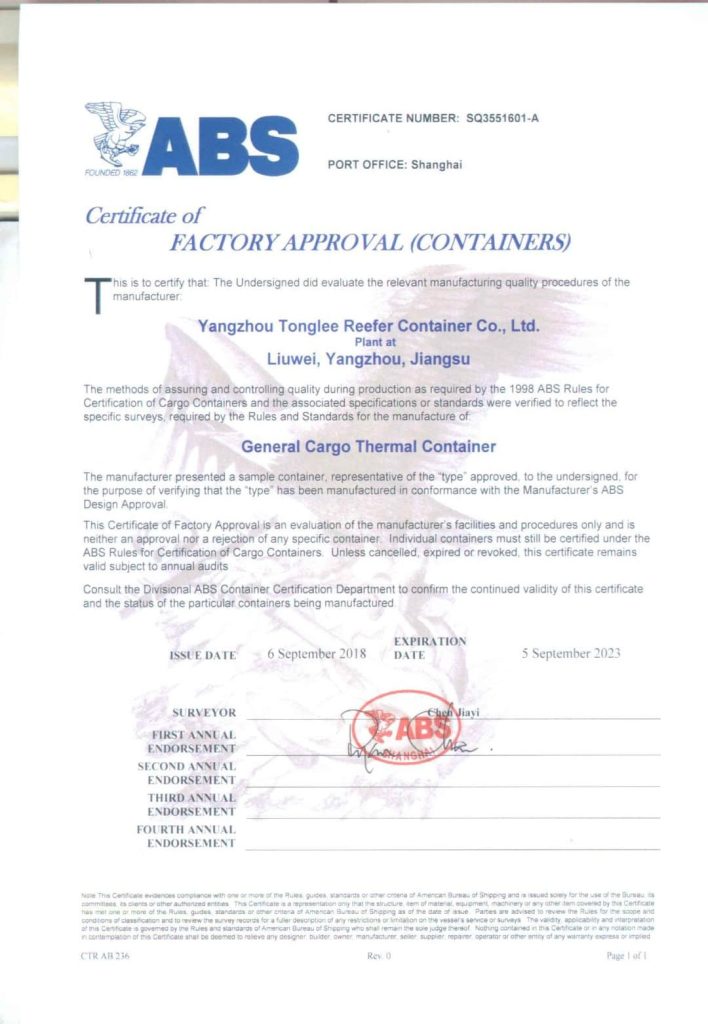

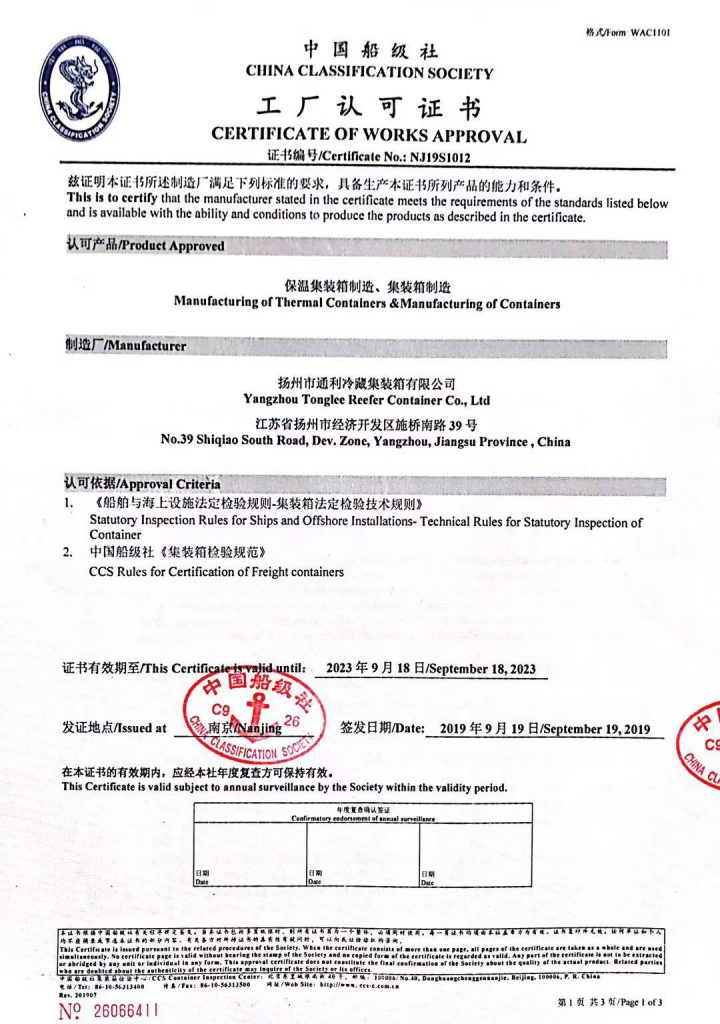

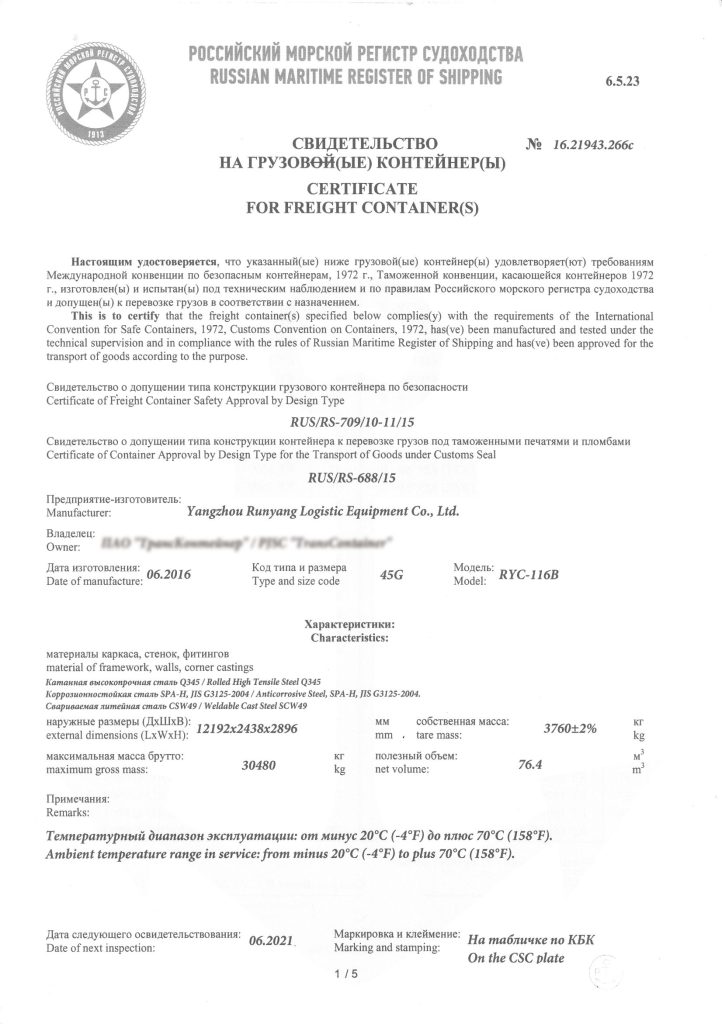

- CIMC TLC|RYC Offshore Living Quarter Certified to DNV2.7-1, A60 fire-proof certification of ABS

- Designed to maximize worker safety and comfort

- Easy plug and play connections with safe and quick installation

Offshore Living Quarter Installation Process

- Production box frame: from processing single parts to welding box, finally assembling the box frame;

- Installation of the flooring;

- Laying insulation materials within the Offshore Living Quarter;

- Installation box concealed works installation of water pipes, installation of ducts, installation of cable trays, etc.

- Install interior decorative wall panels;

- Furniture and appliances in the installation box;

- Test, acceptance of hydropower.

Offshore Living Quarter Data Sheet

| Dimensions | 9800mm L х 3400mm W х3050mmH (32′ Lx ll’Wx 10’Н) | ||||

| Tare Weight | 17,000kgs (27,478 lbs.) | ||||

| Structure | DNV 2.7-1 / BS EN 12079 Includes Lifting Pad Eyes, Slings, and Shackles | ||||

| Bulkheads | Fire Rating: А60 | ||||

| Fire & Gas | F&G Detection / F&G Panel (Optional) | ||||

| Fire Damper | Electro-Mechanical Actuation | ||||

| Protection System | Safe Area Classification | ||||

| Power Requirements | Зрh+Е 380V-480V, 32amp 50/60Hz | ||||

| Climate Control | 1 АС System/Bedroom | ||||

| Design Temperature | -20°C to + 50° C | ||||

Offshore Living Quarter Construction Details

1.Welding of Offshore Living Quarter

CIMC TLC|RYC will make special tooling equipment according to the dimensions and welding process requirements of the box and its parts to control the dimensional tolerance and welding deformation during assembly welding;

All Offshore Living Quarter main structural welds are welded by classification society-certified welders.

After the box welding is completed, we will inspect all weld beads according to the requirements of DNV 2.7-1 standard, and perform magnetic powder, penetration, ultrasonic, and X-ray inspection of the corresponding position of the weld bead.

In the inspection of the Offshore Living Quarter, according to the painting process, the paint matching is suitable for the marine environment, the top of the box is sprinkled with non-slip sand, and the corresponding stickers meet the standard requirements.

2.Installation and Construction of Offshore Living Quarter Pipeline

Before installing ducts, water pipes, etc., we will pre-lay the insulation material, and ensure that the insulation surface is not damaged;

On the Offshore Living Quarter roof, reserve the supporting boom required for the installation pipeline, boom spacing is in line with installation specifications to ensure that the boom is firmly fixed;

We will install the pipeline in the specified position according to the drawing requirements, to ensure that the pipeline is straight, fixed firmly, to avoid loosening during use due to transportation shaking.

3.Testing and Acceptance of Offshore Living Quarter Hydro

Before the acceptance of the Offshore Living Quarter, the relevant personnel will make the acceptance list, which will list the acceptance items and items, acceptance methods and criteria to be met;

Offshore Living Quarter acceptance, the acceptance staff according to the acceptance list of items, items, and criteria one by one test mark the items in the list and supervise the later rectification until the test content meets the standard requirements.

Offshore Living Quarter Flysheet