In today’s globalized world, cold chain logistics has become a key link in ensuring the safe transportation and storage of all kinds of perishable goods, and the container cold room is a well-deserved star equipment in this link. Whether it is fresh fruits shipped from distant production areas to all parts of the world, or pharmaceutical products with strict temperature requirements, the container cold room is silently guarding their quality, ensuring that these goods are not threatened by high temperatures and deterioration during the long journey. Its emergence not only breaks the limitations of traditional cold storage but also reshapes the pattern of cold chain logistics with its unique advantages, injecting strong impetus into the vigorous development of global trade. So, how does this seemingly ordinary container achieve efficient refrigeration and play a key role in cold chain logistics?

How does technology drive

Refrigeration system: Where does the cold come from

The refrigeration core of a container cold room is its refrigeration system. The most commonly used one is the compression refrigeration system, which is like the “heart” of the cold storage, continuously delivering cold to the cold storage. Its working principle is based on phase change and energy transfer in physics, and uses the phase change of refrigerant at different pressures and temperatures to achieve refrigeration.

In this system, the compressor is a key component, which plays an important role in adiabatic compression. Like a hard-working “porter”, it sucks in low-temperature and low-pressure refrigerant gas, and compresses it into high-temperature and high-pressure superheated steam through mechanical work. This process greatly increases the temperature and pressure of the refrigerant, laying the foundation for subsequent heat release. For example, the common piston compressor realizes the compression of the refrigerant through the reciprocating motion of the piston in the cylinder. Although the structure is relatively complex, it has high reliability and can adapt to more stringent working environments, while the scroll compressor uses the relative rotation of the two scroll plates to cleverly realize the compression of the refrigerant. It has the advantages of high efficiency, low vibration, and low noise, and is gradually being widely used in container cold rooms.

The high-temperature and high-pressure refrigerant vapor discharged from the compressor then enters the condenser. The function of the condenser is to condense the gaseous refrigerant into liquid, and this process will release a lot of heat. The condenser is like a “heat dissipation expert”, which dissipates the heat carried by the refrigerant to the surrounding environment through heat exchange with the external cooling medium (usually air or water). Taking the air-cooled condenser as an example, it usually consists of a set of heat dissipation fins and a fan. When the high-temperature and high-pressure refrigerant vapor flows through the fin tube, the fan blows the surrounding air through the fins to accelerate the heat dissipation, so that the refrigerant is quickly cooled and condensed into liquid.

The high-pressure liquid refrigerant, cooled by the condenser, then comes to the expansion valve. As a throttling element of the refrigeration system, the expansion valve plays the role of a “flow regulator”. It throttles and reduces the pressure of the high-pressure liquid refrigerant through a small hole or a narrow slit, turning it into a low-temperature and low-pressure gas-liquid two-phase state. This process is similar to opening a small hole in the high-pressure water flow, allowing the water flow to drop in pressure instantly and produce flash evaporation. Part of the liquid refrigerant quickly vaporizes, thereby absorbing a large amount of heat, which greatly reduces the temperature of the refrigerant.

Finally, the low-temperature and low-pressure gas-liquid two-phase refrigerant enters the evaporator. The evaporator is the key part of the refrigeration system to achieve the refrigeration effect. It is like a “cold releaser”. The refrigerant absorbs the heat of the goods and air in the container in the evaporator, and the liquid refrigerant gradually vaporizes into gas, thereby reducing the temperature inside the container and achieving the purpose of refrigeration and preservation. On the surface of the evaporator, there are usually a large number of heat exchange tubes. These heat exchange tubes increase the contact area between the refrigerant and the air, improve the heat exchange efficiency, and ensure that heat can be absorbed quickly and effectively.

Temperature control: the art of precision

For a container cold room, it is not enough to have a refrigeration system alone. Accurate temperature control is also crucial. It is directly related to the storage quality and safety of goods. The temperature control system is like the “smart brain” of the cold storage. Through a series of advanced technical means, it ensures that the temperature in the cold storage is always kept within the set range.

The temperature sensor is the “tentacle” of the temperature control system. They are cleverly installed in various key positions of the container cold room. They can sense the temperature changes in the cold storage in real time and convert this temperature information into electrical signals, which are accurately transmitted to the controller. These sensors are like sharp “temperature scouts” with high precision, fast response, and good stability. They can capture even extremely small temperature fluctuations in time and provide reliable data support for the controller. For example, the common thermocouple sensor uses the thermoelectric effect of two different metals to convert temperature changes into a voltage signal output. It has high measurement accuracy and fast response speed, which can meet the high requirements of a container cold room for temperature measurement; while the platinum resistance sensor works based on the characteristic that the resistance value of metal platinum changes with temperature. It has the advantages of good stability and a wide measurement range, and also plays an important role in temperature measurement.

The controller is the “commander” of the temperature control system. It receives the signal from the temperature sensor and compares it accurately with the pre-set temperature value. When it is detected that the actual temperature is higher than the set temperature, the controller will quickly issue a command to start the refrigeration system, let the compressor start working, increase the refrigeration capacity, and reduce the temperature in the cold storage as soon as possible; on the contrary, when the actual temperature is lower than the set temperature, the controller will adjust the working intensity of the refrigeration system appropriately according to the specific situation, reduce the refrigeration capacity, or even temporarily stop refrigeration to prevent the temperature from being too low and causing damage to the goods. Some advanced controllers also have intelligent adjustment functions, which can automatically adjust the operating parameters of the refrigeration system according to the temperature change trend in the cold storage, to achieve more accurate and efficient temperature control. For example, the controller using fuzzy control algorithm can automatically judge and adjust the working state of the refrigeration system according to the input temperature signal and the preset fuzzy rules, avoiding the over-adjustment or under-adjustment phenomenon that may occur in the temperature adjustment process of the traditional controller, and greatly improving the stability and accuracy of temperature control.

Wisdom in design

Insulation material: a barrier to protect the cold volume

In the design of a container cold room, the selection of insulation material is crucial. It is like a solid barrier to prevent the invasion of external heat and protect the precious cold volume in the cold storage. At present, polyurethane foam is one of the most widely used insulation materials in container cold rooms. The reason why this material is so popular is that it has an extremely low thermal conductivity, usually between 0.022- 0.028 W/(m・K), which means that heat is difficult to transfer through polyurethane foam. From a microscopic point of view, the interior of polyurethane foam is composed of countless tiny closed-cell structures, which are like closely arranged small rooms with air sealed in them. Due to the poor thermal conductivity of air and the fact that the closed-cell structure effectively prevents air convection, the thermal insulation performance of polyurethane foam has been greatly improved. Just like in the hot summer, when we wear thick down jackets, the air layer inside the down jackets can effectively block the heat from the outside, making us feel cool and comfortable. The role of polyurethane foam in a container cold room is the same.

In addition to polyurethane foam, materials such as polystyrene foam and extruded polystyrene foam are also used to some extent in the insulation of container cold rooms. Polystyrene foam has the advantages of light weight, good thermal insulation performance, and relatively low price. Its thermal conductivity is generally 0.035 – 0.043 W/(m・K). However, its water absorption is relatively large, which may affect the long-term stability of its thermal insulation performance, because the intrusion of moisture will increase the thermal conductivity of the material and reduce the thermal insulation effect. Extruded polystyrene foam has higher compressive strength and lower water absorption, and its thermal conductivity is usually between 0.028 and 0.035 W/(m・K). In some occasions where high insulation performance and structural strength are required, extruded polystyrene foam is a good choice. But in general, polyurethane foam has a dominant position in the insulation field of container cold rooms due to its comprehensive performance advantages.

Sealing technology: prevent cold loss

If insulation materials are barriers to prevent heat intrusion, then sealing technology is the key line of defense to ensure that cold storage does not lose cold. In a cold room, any tiny gap may become a channel for cold leakage, thereby increasing the burden on the refrigeration system and reducing the energy efficiency of the cold storage. Therefore, the use of advanced sealing technology and high-quality sealing materials is crucial to ensure the performance of the container cold room.

In the manufacturing and installation process of a container cold room, commonly used sealing materials include rubber sealing strips, silicone sealants, etc. Rubber sealing strips have good elasticity and low temperature resistance, and can fit tightly to the joints of the cold storage, effectively preventing the leakage of cold air. For example, rubber sealing strips are usually installed on the edge of the cold storage door. When the door is closed, the sealing strips are compressed to form a tight sealing barrier to prevent the exchange of cold air with hot air from the outside. Silicone sealants have excellent weather resistance and sealing performance, and can maintain a stable sealing effect under different environmental conditions. They are often used for sealing between cold storage panels and for sealing the treatment of some special parts. At the corners of the cold storage or some irregular joints, silicone sealants can fill the gaps to form a solid sealing layer to ensure that the cold air will not leak out from these places.

In addition to choosing the right sealing material, reasonable sealing design and installation process are equally important. In the design stage of the cold storage, engineers will carefully consider the connection method and sealing structure of each component to minimize unnecessary gaps and openings. During the installation process, construction personnel need to strictly follow the operating procedures to ensure the installation quality of the sealing material. For the installation of rubber sealing strips, it is necessary to ensure that the installation position is accurate and the sealing surface is flat, and to conduct a careful inspection after installation to ensure that the sealing strips are not damaged or loose; for the construction of silicone sealant, it is necessary to control the thickness and uniformity of the glue to ensure that the sealant can fill the gap and form a good sealing effect. Only by striving for excellence in every link, such as sealing materials, sealing design, and installation technology, can we effectively prevent the loss of cold capacity in the container cold room and ensure the efficient operation of cold storage.

Why is it irreplaceable?

Flexible transportation: adapts to diverse logistics scenarios

One of the biggest advantages of a container cold room is its unparalleled flexibility and mobility, which enables it to perfectly adapt to various complex and changing logistics scenarios.

- In the field of shipping, a container cold room is an indispensable key equipment in ocean transportation. Imagine that starting from Chile in South America, boxes of freshly picked cherries are loaded into a container cold room, and after a half-month transoceanic voyage, they arrive at Shanghai Port, China. During this long journey, the container cold room is like a mobile “low-temperature fortress”, firmly guarding the freshness and quality of cherries. Its standardized design size can perfectly adapt to various ocean-going cargo ships. Through efficient loading and unloading equipment, it can quickly load and unload goods, greatly improving the efficiency and convenience of sea transportation. According to statistics, more than 80% of the fresh goods transported by sea each year in the world are completed with the help of a container cold room, which fully demonstrates its important position in ocean cold chain logistics.

- In terms of land transportation, the container cold room also performs well. Whether it is a refrigerated truck shuttling on the highway or a railway refrigerated train galloping on the rails, the container cold room can be easily loaded to achieve rapid transportation of goods. Compared with traditional refrigerated trucks, a container cold room has higher space utilization and better versatility. It can be flexibly combined and deployed according to the actual needs of the goods. An ordinary truck can transport multiple container cold rooms at the same time, greatly improving transportation efficiency. In some remote areas or mountainous areas with inconvenient transportation, the mobility advantage of the container cold room is more prominent. When encountering sudden natural disasters or urgent material needs, a container cold room can be quickly transported to the disaster area to provide the affected people with much-needed materials and food refrigeration guarantees, becoming an important force in rescue operations.

- In the field of air transportation, the container cold room has also begun to emerge. For some goods with extremely high timeliness requirements, such as high-end pharmaceutical products, rare flowers, etc., air transportation has become the preferred mode of transportation due to its fast and efficient characteristics. The container cold room has been specially designed and modified to meet the strict requirements of air transportation, ensuring that the goods are always in a stable, low-temperature environment during high-altitude flight. Although the cost of air transportation is relatively high, for those high-value, small-volume, and temperature-sensitive goods, the combination of a container cold room and air transportation provides a strong guarantee for their fast and safe transportation.

Efficient storage: ensuring the quality of goods

In addition to its outstanding performance in the transportation link, the container cold room also plays an irreplaceable and important role in the storage link of goods. It is like an efficient “freshness guard” that can effectively maintain the freshness of goods, extend the shelf life of goods, and reduce the loss of goods.

- Take fresh fruit as an example. In a cold container room, the appropriate low temperature environment can significantly slow down the respiration and metabolism of fruits. When fruits are picked, they are still living organisms that will continue to breathe, consume their own nutrients, and generate heat. In a low temperature environment, the respiration intensity of fruits will be greatly reduced, and the consumption rate of nutrients will also slow down, thereby effectively extending the shelf life of fruits. Bananas stored in a cold room at a temperature of 12-14℃ can extend their shelf life to 2-3 weeks, while at room temperature, bananas may start to deteriorate and rot in just a few days. In addition, a container cold room can further optimize the storage environment of fruits by controlling humidity and gas composition. For some fruits that are easy to lose water, such as strawberries and grapes, by maintaining appropriate humidity in the cold storage, the evaporation of fruit water can be reduced, and the fullness and taste of the fruit can be maintained; for some fruits that are sensitive to oxygen, such as apples and pears, the oxygen and carbon dioxide concentrations in the cold storage can be adjusted to inhibit the oxidation process of the fruit and delay the aging and deterioration of the fruit.

- In the field of medicine, the efficient storage function of a container cold room is even more related to the quality of medicines and the life safety of patients. Many medicines, especially some biological products and vaccines, have extremely strict requirements on storage temperature. Once the temperature is out of control, the active ingredients of the medicine may be destroyed, causing the medicine to fail or even produce harmful substances. A container cold room provides reliable protection for the storage of medicines with its precise temperature control and stable operating performance. For example, when transporting and storing the new crown vaccine, the container cold room needs to strictly control the temperature within the range of 2-8℃ to ensure the effectiveness and safety of the vaccine. By real-time monitoring and adjusting the temperature, as well as being equipped with a complete backup power supply and alarm system, a container cold room can effectively respond to various emergencies and ensure the stability of the quality of medicines during storage and transportation. According to relevant data, the use of a container cold room to store medicines can reduce the loss rate of medicines to less than 1%, greatly improving the reliability and safety of medicine supply.

Container cold room, the future of the cold chain

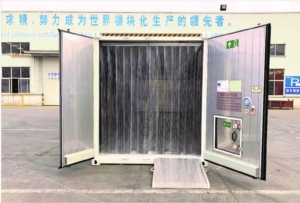

container cold room, a key equipment in cold chain logistics, has achieved efficient refrigeration and precise temperature regulation with its unique refrigeration system and temperature control technology; the carefully designed insulation materials and sealing technology provide a solid guarantee for its efficient operation; the advantages of flexible transportation and efficient storage enable it to play an important role in various logistics scenarios and become a reliable force to ensure the quality of goods.

CIMC TLC|RYC|XLC is a leading manufacturer of container cold rooms and various other standard and special logistics equipment. With years of experience in the industry, it focuses on the design, production, and distribution of high-quality innovative products that meet the specific needs of customers.

If you need high-quality and innovative logistics equipment, including refrigerated containers, cold chain equipment, containerized equipment integration, modular buildings, etc., CIMC TLC|RYC|XLC is your best choice. We welcome inquiries from customers all over the world and look forward to the opportunity to cooperate with you.