Concrete Mixing Module is combined by several containers, which equipped with mixer system and conveyor system, mix system is consist of electric&hydraulic drivers, mechanical gear reducers and foot mount configurations. Conveyor system is consist of accessible drives and belt tensioning system, the entire system can mix up to 400 compacted cubic meters of concrete per hour.

If you’ve been in the construction industry, you know how important it is to have a high-quality concrete mix for any project. Traditional mixing methods require a lot of space, time and labor, and are expensive and time consuming. This is where the concrete mixing plant container comes in. This innovative product provides a compact, efficient and reliable solution for all your concrete mixing needs.

A concrete mixing plant container is a container-based concrete mixing plant that combines multiple components into a single transportable unit. This module includes everything needed to produce high-quality concrete mixes, including mixers, batching systems, conveyor belts and other components. The modular design makes it easy to transport and install on any job site, and it can be customized to meet your specific needs.

CIMC TLC|RYC Concrete Mixing Module Introduction

- Easy to assemble plants modules with simple container twist locks

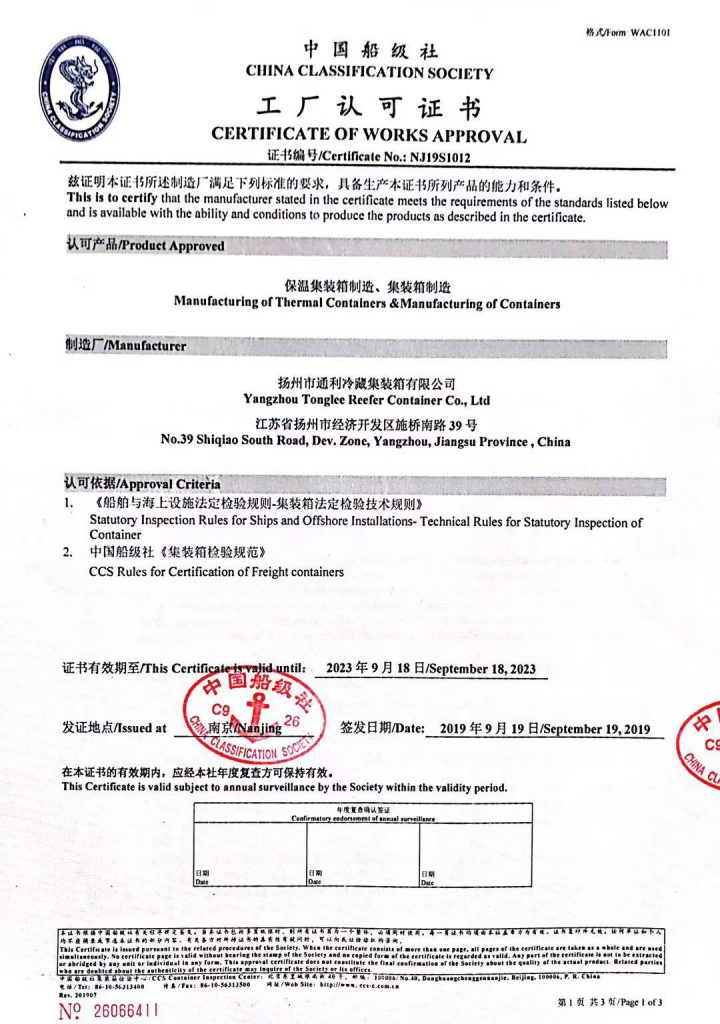

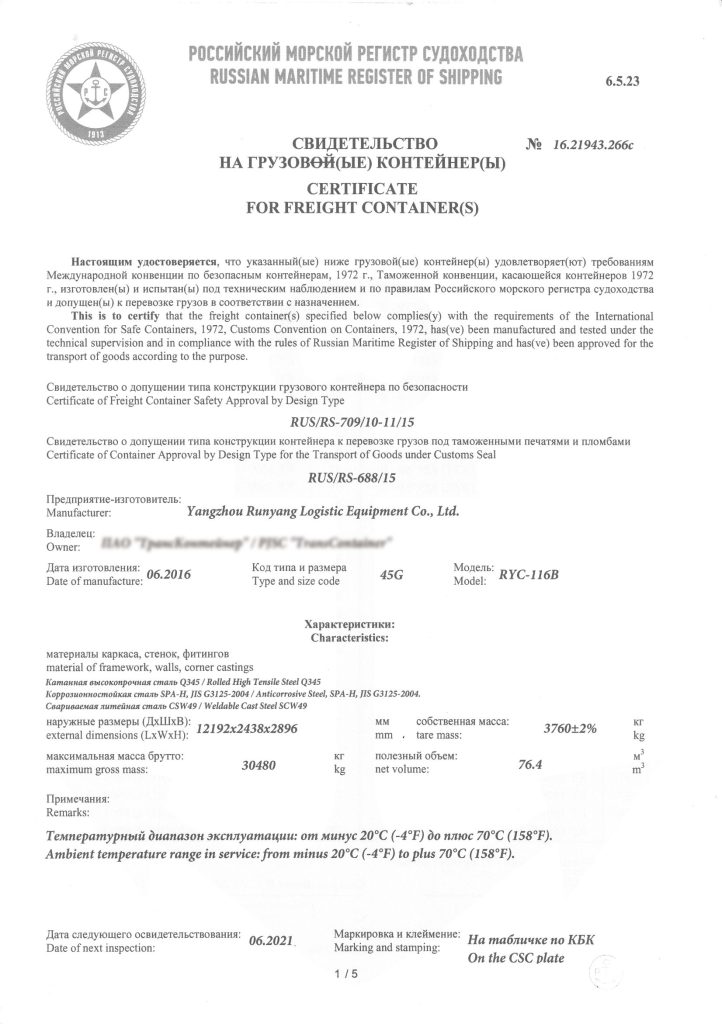

- Efficiently transported – all Concrete Mixing Module is 40ft certified CSC shipping containers

- Structure design to ensure long span rigidity without unnecessary weight penalties

- Easy to clean and easy to service, Has the power to handle the most difficult materials

- Excellent accuracy and proportioning of ingredients, Mix up to 400 compacted cubic meters of concrete per hour

- Accessible and reliable drives and belt tensioning systems

- Enclosed conveyor systems for dusty environments and/or cooled aggregates

Attributes

- Robust and sturdy construction

- Easy to assemble and disassemble

- Equipped with high-quality components

- Can be customized according to specific requirements

Functions

- Mixing and producing high-quality concrete

- Suitable for different types of concrete, including lightweight, heavy-duty, and standard mixes

- More efficient and cost-effective than traditional concrete plants

- Reduces transportation costs and minimizes environmental impact

Advantages

- Cost Savings

- The compact design and easy assembly save on installation time and labor costs

- Eliminates the need for a permanent concrete plant structure

- Low-maintenance reduces operational costs

- Flexibility

- Can be transported easily to various job sites

- Customizable according to specific needs

- Suitable for both short-term and long-term projects

- 品質管理

- Precise measuring and mixing ensure consistent quality

- Equipped with advanced technology to monitor and control the mixing process

- Produces a range of high-quality concrete types

Features and Benefits of Concrete Mixing Modules

Concrete mixing modules have several features and benefits that set them apart from traditional concrete mixing methods.

compact design

The module’s container-based design makes it compact and easy to transport. It can be loaded onto a standard truck or trailer and taken to any job site. This design also means that the module takes up less space than a traditional mixing plant, making it ideal for smaller workplaces or areas with limited space.

modular structure

concrete mixing plant container means it can be easily customized to meet your specific needs. You can add or remove components as needed to create the system that best suits your project. This flexibility also means that the module can be easily upgraded or expanded as your needs change over time.

easy to use

The concrete mixing module is designed to be easy to use, even for those with limited experience in concrete mixing. The ingredient system and mixer are fully automatic, which means you don’t need to manually measure or mix ingredients. This automation also ensures consistent mixing and reduces the risk of error.

high quality mixing

Concrete mixing modules use advanced technology to ensure the highest quality mixes every time. The mixer is designed to produce a consistent mixture, and the dosing system ensures that the correct amount of each ingredient is used. This technology helps reduce waste and ensures that every mix is made to your exact specifications.

Cost-effectiveness

The concrete mixing module is a cost-effective concrete mixing solution. It can save you labor and equipment costs by eliminating the need for manual labor and reducing the amount of space required. Plus, the automated dosing system helps reduce waste, saving you money on materials.

Application of Concrete Mixing Module

Concrete mixing modules are suitable for a variety of construction projects including:

- highways and roads

- bridge

- tunnel

- buildings and structures

- Airport

- Dams and Reservoirs

The module can produce a wide range of concrete mixes including standard mixes, high strength mixes and specialty mixes. This flexibility makes it an excellent choice for any project requiring a high-quality concrete mix.

Installation and maintenance of concrete mixing module

Installation and maintenance of concrete mixing module

Installing and maintaining the concrete mixing modules is straightforward. The module can be easily transported to the job site, and the setup process is quick and easy. Once the module is set up, minimal maintenance is required to keep it running smoothly. Regular cleaning and inspection of components is all that is needed to keep your system running at peak efficiency.

Concrete Mixing Module Product Performance

High Quality Stirring Performance

Concrete Mixing Module is equipped with double horizontal shaft forced mixer, short stirring time, good mixing quality, for dry hard, half-day hard, plastic and various ratio concrete can be stirred.

Simple Operating Performance

The Concrete Mixing Module machine adopts computer control, which can be controlled automatically or manually. Live panel display allows the operator to clearly understand the operation of each component.

Precise Metering Performance

Whether it is aggregate, powder, or water agent metering and control elements, CIMC TLC|RYC Mixing Module adopts imported components, microcomputer control. Sampling speed of over 120 times/sec, fully guaranteed accuracy and stable working performance.

Good Maintenance Performance

Concrete Mixing Module has a walkway or ladder for each maintenance and repair site, which is intuitive and has plenty of room for operation.

Industrial Design

The entire design process of Concrete Mixing Module combines ergonomics and aesthetics, making the machine beautiful appearance, reasonable structure layout, comfortable operation and easy maintenance.

Convenient Transitions

The overall structure is modular. Dosing machine, belt conveyor, stirring main building, screw conveyor and powder tank are independent structure.

Mixing main building consists of several separate modules. Disassembly, installation quickly, easy to transport and fast. Concrete Mixing Module is available in a variety of forms to suit the needs of different venues.

Excellent Environmental Performance

All powdered materials, from feeding, dosing, dosing, dosing to stirring unloading are carried out in a closed state. Floor mounted mixing platform and fully enclosed aggregate belt conveyor greatly reduce the pollution caused by dust and noise.

Control System

Concrete Mixing Module uses an industrial control computer, 1/O acquisition and high-precision weighing system to achieve automatic control of data acquisition and production by control software according to concrete production process and quality requirements, and record production data information in real time, using data management to query/print a variety of production reports.

Concrete Mixing Module Data Sheet

| 外寸 | 12192(L) x 2438(W) x 2896(H) mm | |

| 風袋重量 | 6000 -8000 kg for each module | |

| 屋根 | Frame structure | |

| Sidewall | Partition or strengthening pillar & handrail | |

| End wall | T3.0mm SPA-H + strengthening pillar or handrail. | |

| フロア | Patterned steel floor or Grating | |

| Mixer System | Mixers are available with electric and hydraulic drives. The power required depends upon the material type and throughput. Mechanical gear reducers are available in both shaft to mount foot mount configurations, with or without fluid couplings | |

| Conveyor System | Accessible and reliable drives and belt tensioning systems Belt scrapers systems which represent the latest in cleaning technology and maintenance Structure design to ensure long span rigidity without unnecessary weight penalties | |

CIMC TLC|RYC Concrete Mixing Module Service Details

| プリセールスサービス | 技術・商業コンサルタント カスタマイズされたデザインとエンジニアリング |

| 返品ポリシー/アフターサービス | 構造体1年保証 塗装に3年 デカール5年 |

| リードタイム | 70 days after order confirmation |

| 輸送方法 | 海、鉄道、道路 |

| 貨物輸送期間 | 特定の目的地に応じて確認 |

| MOQ | 1 set |

Conclusion The Concrete Mixing Plant Container is an innovative and efficient solution for concrete production. It provides a cost-effective and flexible alternative to traditional concrete plants while delivering consistent quality. Its durable construction and customizable features make it an ideal choice for those seeking a reliable concrete mixing solution.

The outstanding concrete mixing plant container is a compact, efficient and reliable solution for all your concrete mixing needs. Its container-based design, modular construction and advanced technology make it a cost-effective and flexible solution for any construction project. With its high quality mixing, ease of operation and minimal maintenance requirements, concrete mixing modules are