Containerized solution to accommodate different capacity and temperature control systems of Static Var Generator, SVG Equipment Container is used in Photovoltaic/Wind power station, steel mill, high-speed station, etc to improve stability and capacity of power transmission.

SVG Equipment Container Product Benefits

- operation, strong impact resistance, anti-theft, anti-vandal ability, fireproof capacity

- strong anti-rust ability

- double, sealed box, dustproof, moisture-proof, anti-condensation;

- SVG Equipment Container is small in size and compact in structure;

- force analysis according to customer load-bearing needs, optimization of the box structure;

- SVG Equipment Container interior decoration and circuit are completed in the factory, reducing the cumbersome construction work on site

- SVG Equipment Container is quick to install and reliable in waterproof effect.

SVG Equipment Container Performance

- SVG Equipment Container adopts upper and lower air supply structure system, an internal increase of active high-density dustproof device, double exhaust system to facilitate power electronic equipment dust, ventilation, heat dissipation.

- The bottom of the SVG Equipment Container adopts an anti-slip pattern plate and anti-static glue to protect the internal product.

- SVG Equipment Container decoration using high-density rock wool purification board, enhance the internal insulation and heat insulation effect, to ensure the normal operation of equipment in high and low temperature environment.

- The SVG Equipment Container is equipped with emergency lighting system and fire-stop equipment.

CIMC TLC|RYC SVG Equipment Container Benefits

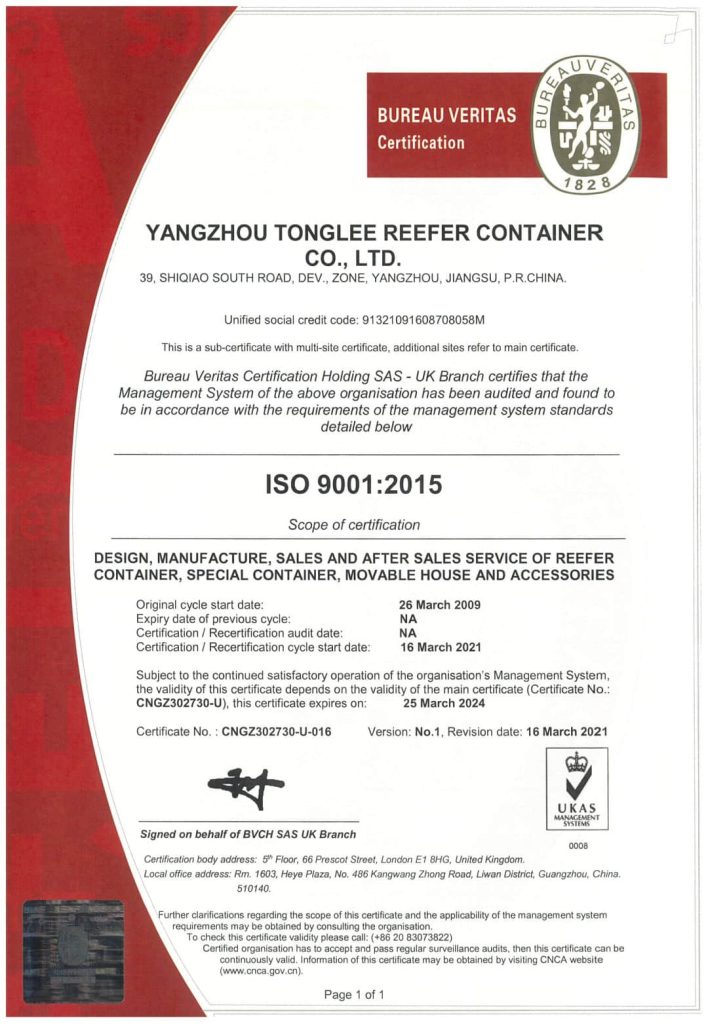

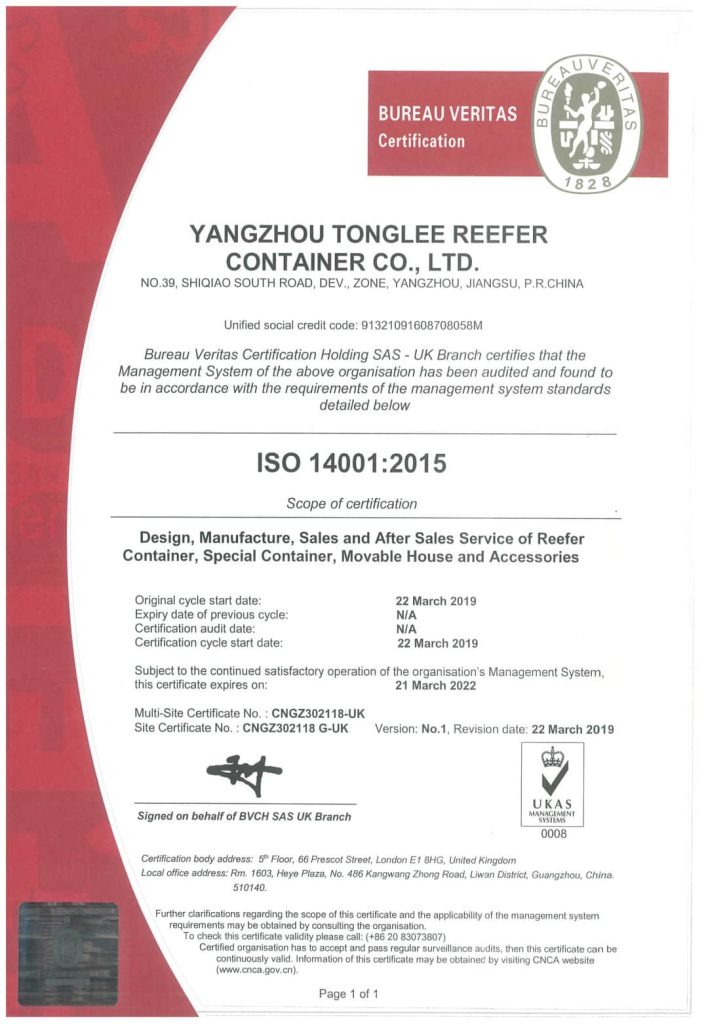

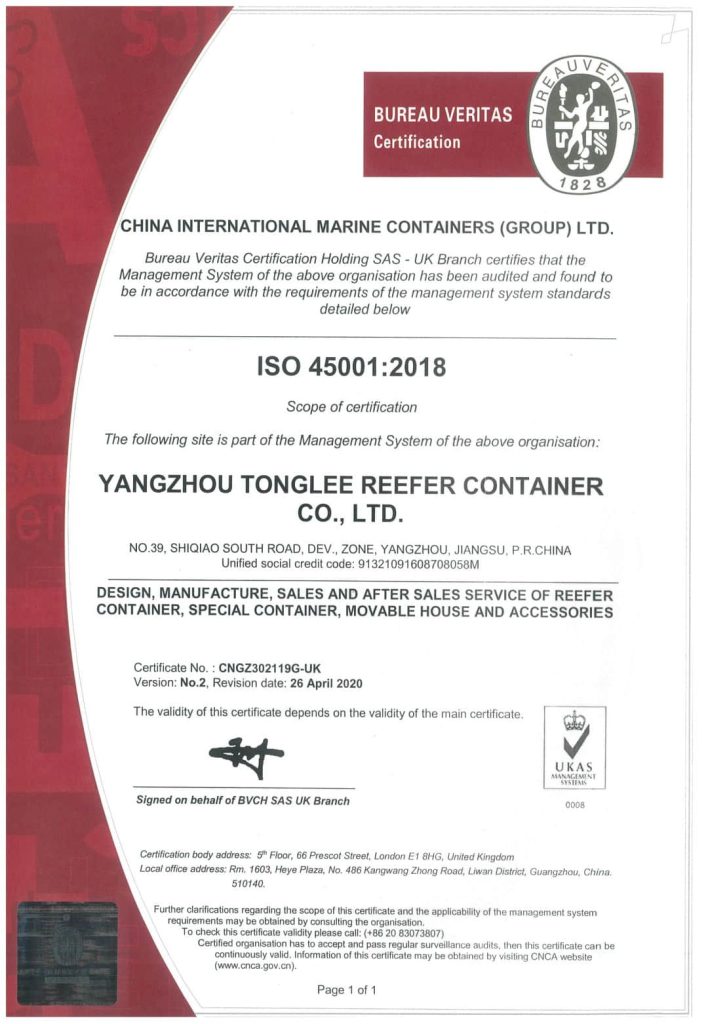

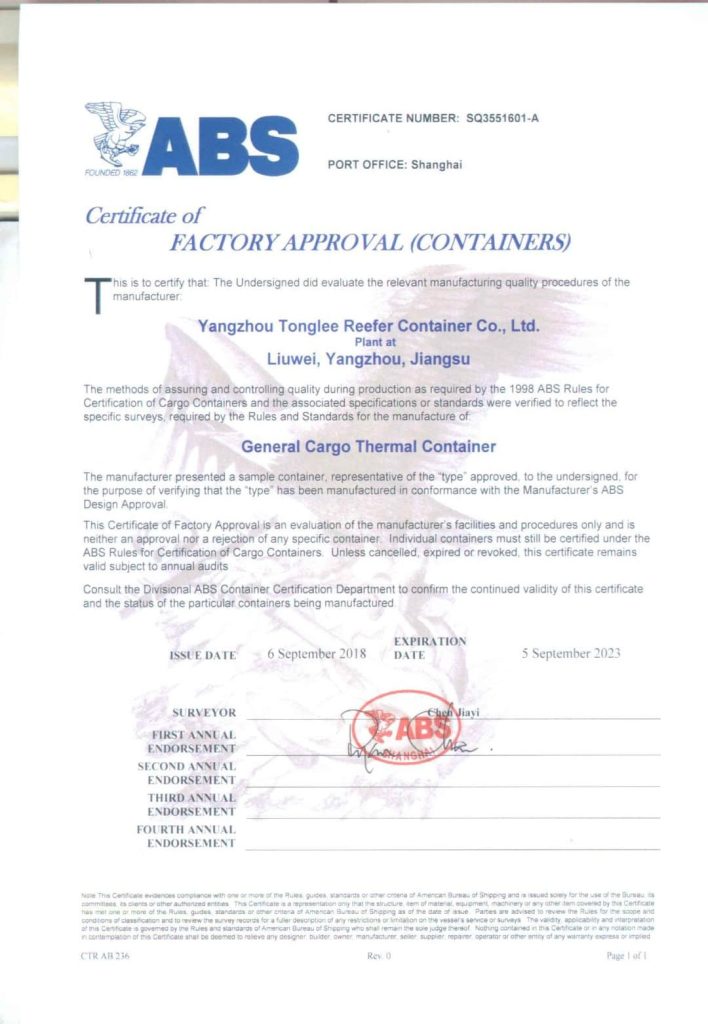

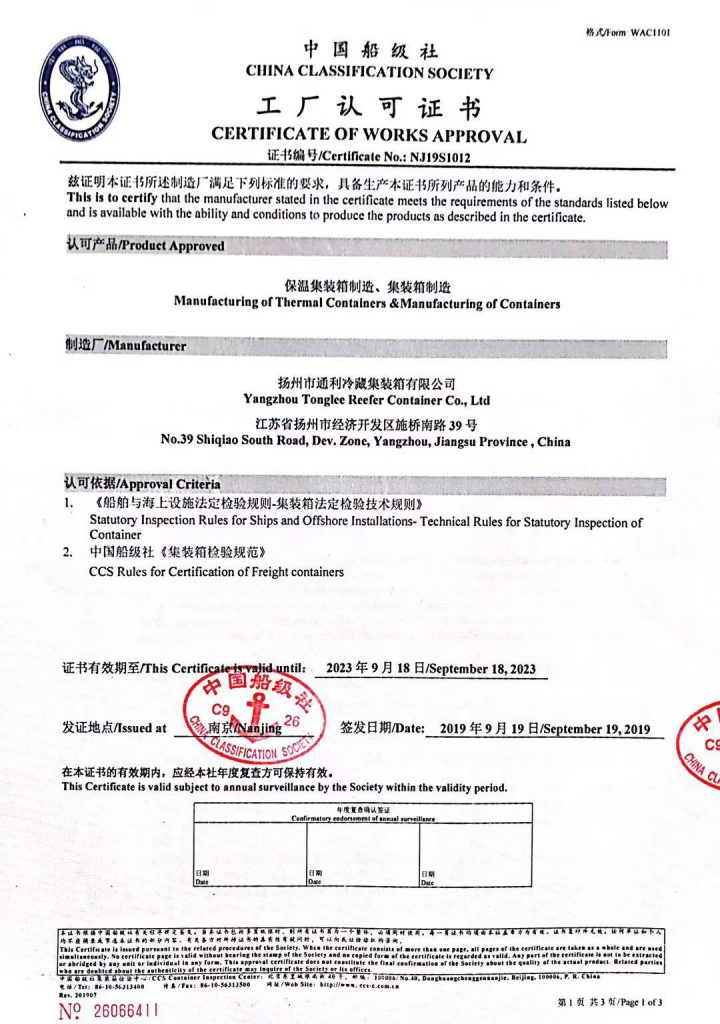

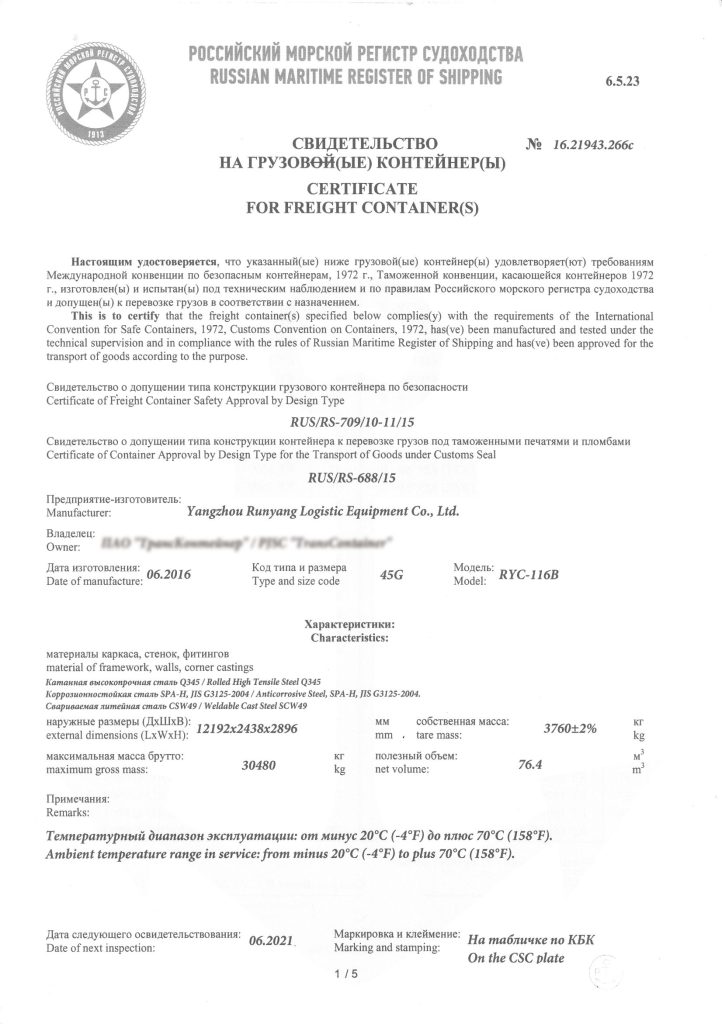

1. Adhere To High Quality

SVG Equipment Container corner parts with standard corner parts, external side, and roof using Q235 or weather-resistant steel (according to the use environment and load to determine the type of material), spraying using the marine heavy anticorrosive coating.

2. Support Free Customization

CIMC TLC|RYC can customize the SVG Equipment Container according to the requirement of equipment, configuration, sound insulation, and fire proof.

3. Lower Cost

More than 90% of construction projects can be completed at the CIMC TLC|RYC Container plant. After the SVG Equipment Container is transported to the site, only need to make power connection and commissioning, reducing the cumbersome on-site construction, saving costs.

4. Lower Transportation Costs

SVG Equipment Container can move with the vehicle to meet the needs of long-distance transportation and comply with road traffic regulations.

5. ShortLead Time

CIMC TLC|RYC has a batch production line and professional technicians, SVG Equipment Container passed strict quality inspection, with high production efficiency and short delivery time.

SVG Equipment Container Data Sheet

| External Size | 10700(L) x 3000(W) x 2800(H) mm | |

| Internal Size | 10600(L) x 2900(W) x 2718(H) mm | |

| Tare Weight | 6000 kg | |

| Roof | T1.6mm SPA-H +T50mm rock wool and 1.2mm galvanized sheet | |

| Sidewall | T1.6 mm SPA-H +T50mm rock wool and 1.2mm galvanized sheet | |

| End wall | Insulated double doors | |

| Floor | T4.0mm steel floor | |

| Door | Insulated double door | |

| Electrical System | Including lighting system | |

| Optional fixtures | None | |